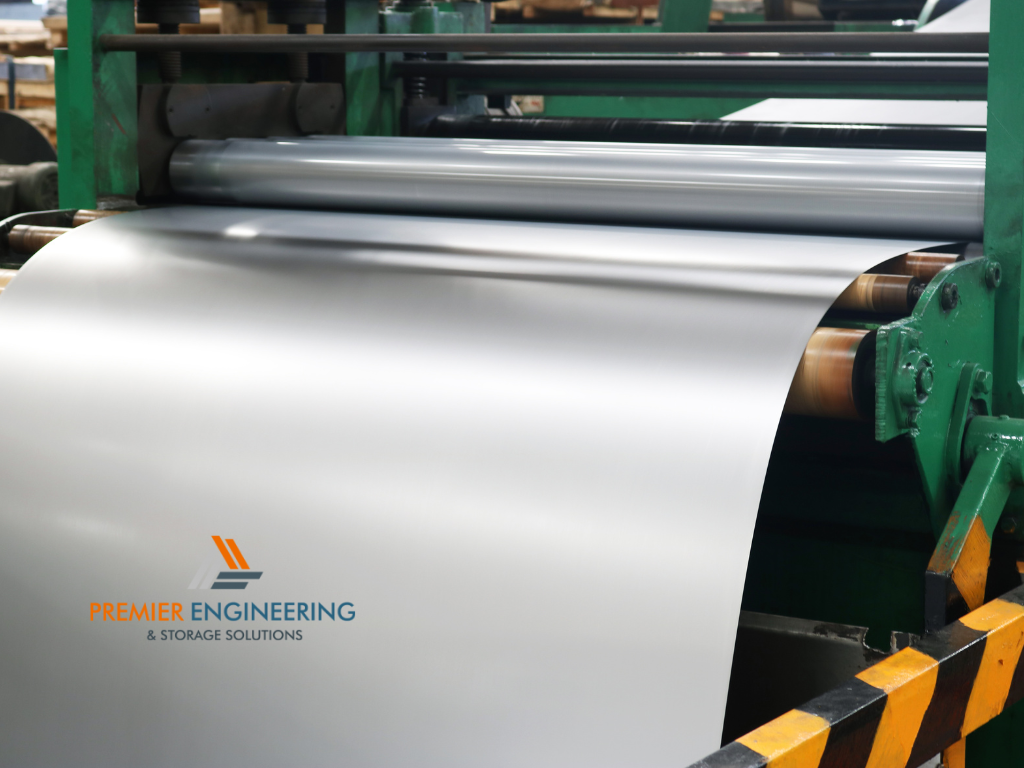

Choosing the right metal is one of the most important parts of cnc sheet metal fabrication. The metal you use will decide how strong, flexible, and long-lasting your final product will be. If the wrong metal is used, parts can bend, rust, or wear out much faster. Getting this choice right from the start saves time and money. It also helps avoid problems later on, like having to redo or replace faulty parts. In many projects, this choice can even affect safety.

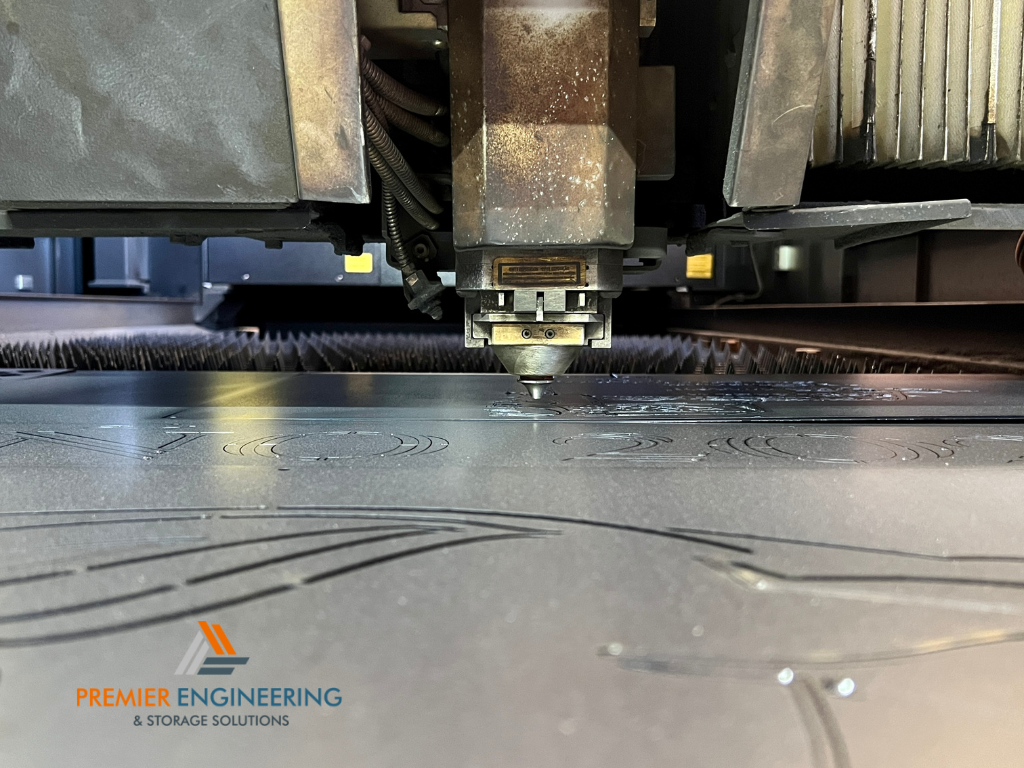

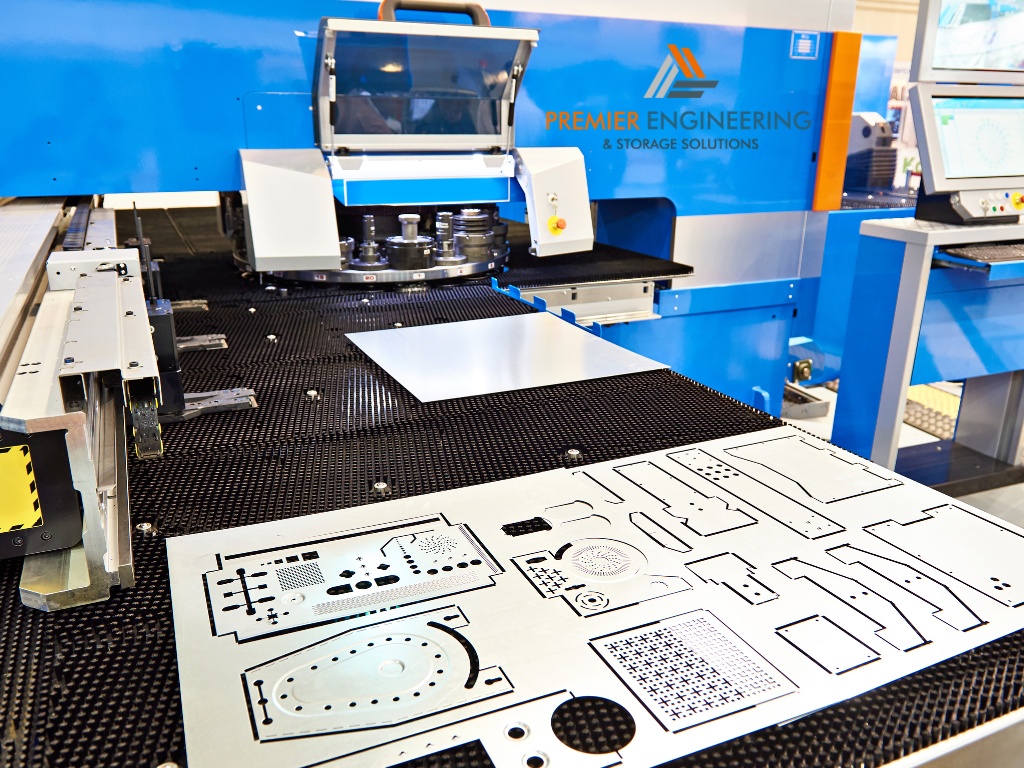

Different metals react differently to heat and pressure. Some are soft and easy to bend, while others are tough and need special tools to cut. Knowing these differences helps you plan ahead and get the best result. Using services like cnc punching service, turret punching services, or laser cutting service also works better when the metal suits the method. So before starting, it’s worth looking at what each metal can do.

Aluminium – Lightweight and Versatile

Easy to Shape and Cut

Aluminium is a popular choice in cnc sheet metal fabrication. It’s light, strong, and doesn’t rust. This makes it perfect for parts that need to be carried, lifted, or moved often. Because it’s soft, aluminium is easy to shape and cut using laser cutting or cnc punching service.

Great for Everyday Products

You’ll often find aluminium used for things like panels, cases, brackets, and frames. It’s also used in cars, electronics, and furniture because it’s simple to work with and looks good. When used with turret punching services or Metal punching services, aluminium can be made into clean, precise shapes without cracking or warping.

Here are a few reasons aluminium is often chosen:

-

It resists corrosion and lasts a long time

-

Light but strong and durable

-

It can be cut and shaped quickly

-

It works well with most cutting and punching tools

Because aluminium is easy to handle, it’s a great choice when time and accuracy matter.

Stainless Steel – Strong and Long-Lasting

Stainless steel is another common choice in cnc sheet metal fabrication. It’s known for its strength and smooth, shiny look. Unlike mild steel, it does not rust easily. This makes it ideal for both indoor and outdoor products.

It is tougher to cut than aluminium, but it handles laser cutting service and Metal punching services well. It holds its shape during fabrication and stays strong even after long use. This is why it’s often used for heavy-duty parts like machine panels, kitchen equipment, and building features.

Stainless steel is also great when appearance matters. It keeps its shine and looks clean, even after years of use. If you want something that lasts and looks good, stainless steel is a reliable choice.

Copper – Conductive and Attractive

Great for Electrical Parts

Is it a useful metal in cnc sheet metal fabrication because it conducts electricity well. It’s often used for electrical parts, wiring strips, and bus bars. Copper handles turret punching services and laser cutting service smoothly when done with care. Its soft surface needs gentle handling to avoid scratches.

Adds a Stylish Look

Copper is also chosen for its warm, reddish colour. It adds a stylish look to decorative items, signs, or high-end products. Designers often pick it when they want something that looks unique but still works well.

Copper is more expensive than other metals, but it gives a mix of beauty and performance that few materials can match. When treated well, it lasts a long time and develops a natural finish that many people find appealing.

Mild Steel – Budget-Friendly and Reliable

Mild steel is one of the most widely used metals in cnc sheet metal fabrication. It’s strong enough for many jobs but still easy to shape and cut. This makes it ideal when you need large amounts of metal at a lower cost. It works well with cnc punching service and laser cutting, producing clean and accurate parts.

It bends easily without cracking, which is handy for frames, brackets, and enclosures. The only downside is that mild steel can rust. To prevent this, it’s often painted, powder coated, or plated. This gives it a longer life while keeping costs low.

People often choose mild steel for:

-

Large production runs

-

Projects with tight budgets

-

Parts that will be coated or painted

-

Basic structural or support pieces

If you need something simple, tough, and affordable, mild steel is a smart choice.

Choosing the Best Metal for Your Project

Think About Use and Budget

Each metal brings something different to cnc sheet metal fabrication. Aluminium is great for light and portable parts. Stainless steel is strong and long-lasting. Copper is perfect when looks and conductivity matter. Mild steel is best for saving money on big projects. Always consider where and how your parts will be used, as well as how long they need to last.

Match Metals with the Right Services

It’s also important to match the metal to the right service.

-

laser cutting service works well for detailed and clean cuts

-

Metal punching services are faster for high-volume jobs

-

turret punching services are great for repeated patterns

Choosing the right mix of metal and service gives you better results and saves time. It also helps avoid mistakes and wasted materials. With the right plan, your project can be finished faster, look better, and last longer.