The sheet metal manufacturing process is a complicated process that involves many steps

The sheet metal manufacturing process is a complicated process that involves many steps

The first step in the sheet metal manufacturing process is to cut the metal into the desired shape. This can be done by using a plasma cutter, shears, or saws. The sheets are then cut to size and placed on a conveyor belt for inspection. Once they have passed the inspection, they are sent to the next step in the process.

The next step in the process is to weld together any seams on the sheets of metal with a gas torch and then place them on a conveyor belt again for inspection. If they pass this inspection, they are sent to be painted or finished for packaging and shipping.

Sheet metal manufacturing is an industry that has been around for a very long time. It is one of the oldest forms of metalworking, and it has evolved and changed over the years.

Sheet metal fabrication is a process that can be broken down into many different steps. The first step in the process is to take raw materials and form them into flat sheets. These sheets are then cut to size and shaped using various types of equipment like shears, punches, and presses. The next step in the process is to attach these pieces together with rivets or other fasteners. Finally, they are typically painted or coated with some type of protective material so they can be used in their desired applications.

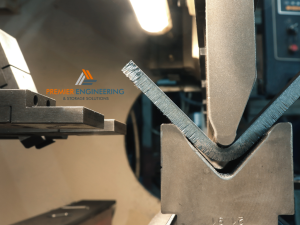

Sheet metal manufacturing is a process that involves the shaping of metal sheets, or metal plate. The process can be done by cutting, punching, bending, and rolling. The main objective of this process is to create a desired shape from the metal sheet.

The most popular types of sheet metal are stainless steel, aluminum, and galvanized steel.