Steel fabrication is a critical process in manufacturing that involves cutting, bending, and assembling steel to create various structures and products. This process is essential across multiple industries, including construction, automotive, and shipbuilding, due to steel’s durability and versatility. The ability to fabricate steel into a wide range of shapes and sizes allows industries to achieve designs that meet specific functional and aesthetic requirements.

Advancements in Fabrication Technology

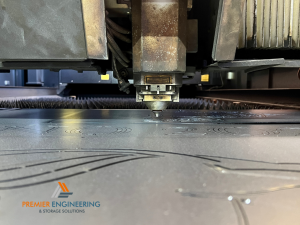

The field of steel metal fabrications has seen significant technological advancements, particularly with the integration of automation and precision tools. Laser cutting, one of the most notable innovations, has revolutionized how steel is cut, offering unmatched precision and efficiency. This technology allows for intricate cuts without physical contact with the material, minimizing wear and tear and improving the quality of the final product.

Steel Laser Cutting Services

Overview of Steel Laser Cutting

Steel laser cutting employs a high-powered laser beam to cut through steel with precision. This process is controlled by computer numerical control (CNC) systems, which ensure high precision and consistency across multiple cuts. Two primary types of lasers are used in steel cutting: CO2 lasers, which are traditional and widely used due to their efficiency in cutting through thick steel plates, and fiber lasers, which are newer and faster with a higher efficiency in electricity conversion.

Benefits of Laser Cutting in Fabrication

Laser cutting stands out in the fabrication process for several reasons:

- Precision and Efficiency: Laser cutting provides unparalleled precision, which is crucial for complex designs and tight tolerances required in high-specification industries.

- Repeatability: With CNC control, laser cutting can produce consistent results across high-volume orders, essential for large projects requiring uniformity.

Applications of Laser Cut Steel Components

Industrial Applications

Laser-cut steel components are integral in industries that demand precision and reliability. In the automotive industry, laser cutting is used to fabricate parts with precise dimensions that are crucial for safety and performance. Aerospace applications similarly rely on the accuracy of laser-cut pieces to meet strict regulatory standards.

Innovative Uses in Design

Beyond industrial applications, laser-cut steel is also used in more creative and architectural contexts. It enables architects and designers to realize unique and intricate designs that were previously not possible. From decorative elements in buildings to bespoke furniture, laser-cutting opens up new possibilities in both aesthetics and functionality.

Integrating Laser Cutting with Other Fabrication Techniques

Complementary Techniques

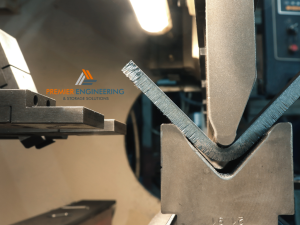

Laser cutting is often integrated with other fabrication methods such as bending, welding, and assembly to streamline production processes. This integration allows for the creation of complex structures and components with high precision and minimal processing time. By combining laser cutting with bending, for example, manufacturers can produce parts that are ready for assembly almost immediately after cutting, reducing the need for secondary processing.

Challenges and Solutions in Steel Laser Cutting

Technical Challenges

The precision of laser cutting, while beneficial, also presents challenges such as the potential for material warping due to high heat input. Solutions include optimizing laser settings for speed and power, using assist gases to enhance cut quality, and employing advanced cooling techniques to manage heat impact.

Optimizing Operations

Efficiency in laser cutting operations can be improved by regularly maintaining equipment, using software to optimize nesting and reduce material waste, and training operators to handle various materials and thicknesses effectively.

Future of Steel Laser Cutting Services

Technological Innovations

The future of steel laser cutting is promising, with potential advancements in laser technology, such as increased cutting speeds and the ability to cut thicker materials more efficiently. Innovations in automation and data analytics are also expected to enhance the precision and efficiency of laser cutting machines.

Market Trends

The market for laser cutting services is anticipated to grow due to increased demand from industries such as automotive, aerospace, and construction. The shift towards customization and rapid prototyping is also driving the adoption of advanced laser cutting solutions.

Choosing a Steel Laser Cutting Service Provider

Criteria for Selection

Selecting a steel laser cutting service involves several critical considerations to ensure high-quality outcomes. Important factors include:

- Capacity: Assessing the provider’s capability to handle the volume of work required.

- Expertise: Evaluating the technical and operational knowledge of the provider in steel laser cutting.

- Equipment: Ensuring the provider uses state-of-the-art technology that can meet the specific needs of your projects.

Partnering for Success

Building a successful partnership with a laser cutting service provider is crucial for long-term benefits. Tips include:

- Communication: Establish clear and consistent lines of communication.

- Collaboration: Work closely with the provider to align objectives and expectations.

- Feedback and Adjustment: Regularly provide and receive feedback to fine-tune processes and improve outcomes.

Conclusion

The field of steel metal fabrications is continually evolving with advancements in technology. Embracing innovative approaches and technologies in steel laser cutting not only enhances capability but also provides a competitive edge in the marketplace. Businesses are encouraged to explore new methods and technologies to stay ahead in the industry.