Technology keeps moving forward, and the cnc cutting machine world is no different. Innovation is not just exciting — it’s necessary. As industries demand faster production and higher precision, users of cnc cutting machines need better solutions to keep up.

New designs help machines cut more accurately and handle tougher materials with ease. Upgraded software also allows operators to program machines faster and fix errors before they cause delays. Without these innovations, businesses could fall behind their competition.

New features making cnc cutting machines faster and smarter

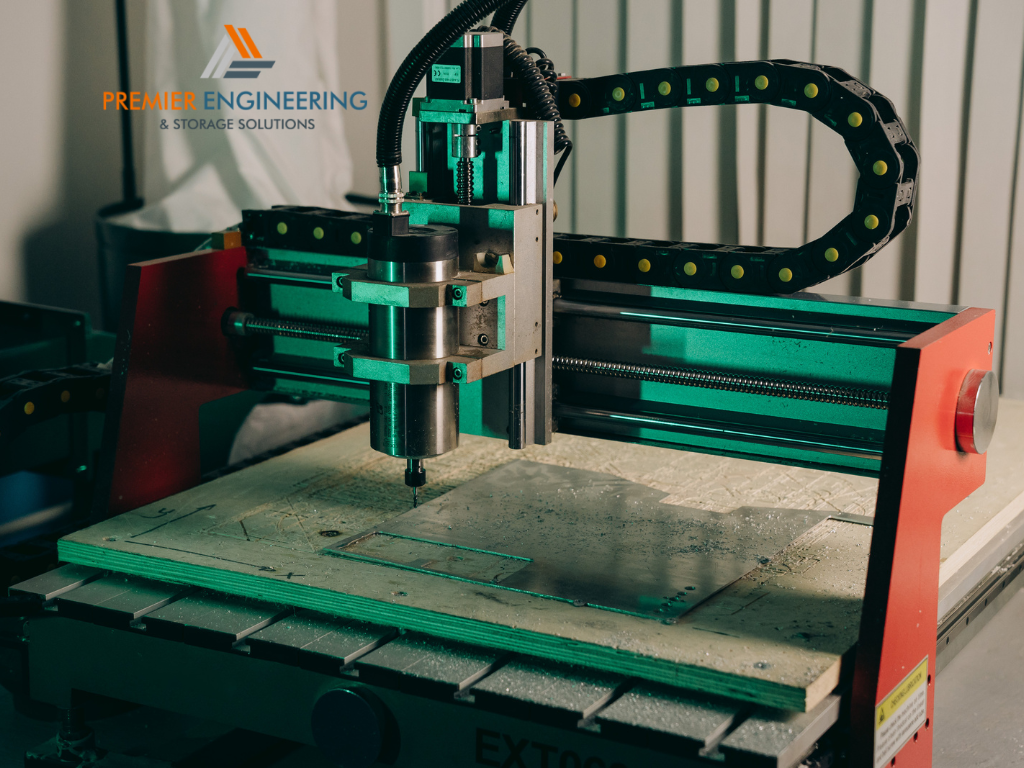

Today’s cnc cutting machines are smarter than ever. Many new models come with automatic tool changers, faster cutting speeds, and better cooling systems. These features reduce downtime and increase overall productivity.

Smart monitoring is another exciting update. Some cnc cutting machines now track their own performance and alert users about maintenance needs. This helps prevent breakdowns and saves a lot of time and money over the life of the machine.

The Growing Role of CNC Sheet Metal Fabrication

How cnc sheet metal fabrication is changing industries

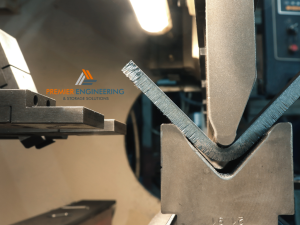

Cnc sheet metal fabrication is playing a bigger role across many industries. From automotive to construction, companies now rely on cnc machines to create strong, precise metal parts quickly.

Instead of taking days to complete one job by hand, cnc sheet metal fabrication allows companies to produce large batches with exact measurements. This speed helps businesses meet growing demands without sacrificing quality.

In fact, custom fabrication projects that once took weeks can now be completed in a few days with the right cnc cutting machine.

What new trends are shaping cnc sheet metal fabrication

One big trend in cnc sheet metal fabrication is the move toward automation. Robots and smart systems now work alongside human operators to speed up production even more.

Another trend is eco-friendly fabrication. Companies are choosing machines that use less energy and create less waste. This shift helps both the environment and the bottom line.

Lastly, the demand for even finer precision continues to grow. New cnc cutting machines can handle micro-cutting tasks, opening up new possibilities for tiny, detailed parts in industries like electronics and medical equipment.

Laser Cutting Service: A Big Part of the CNC Future

Why more companies are offering laser cutting service

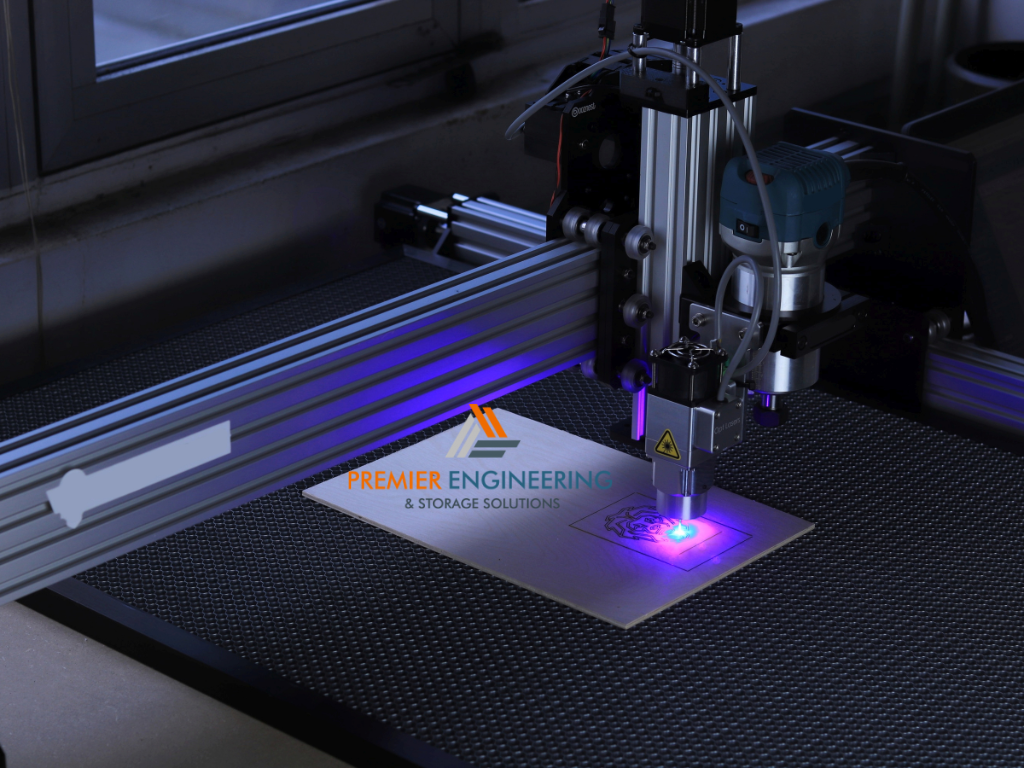

As technology improves, more businesses are adding laser cutting service to their list of offerings. That’s because laser cutting provides unmatched precision, allowing for clean edges and detailed designs that other methods can’t easily match.

Using a laser cutting service also reduces material waste, which saves companies money. Since the process is faster and more accurate, many industries — from fashion to aerospace — now rely on laser cutting service for custom projects and high-volume production.

How laser cutting service is getting faster and more precise

Today’s laser cutting machines work much faster than older models. They can slice through metal, plastic, and wood with incredible speed and leave almost no rough edges.

Some advanced laser cutting systems even adjust automatically to the material type and thickness, making each cut perfect without needing manual changes.

This growing speed and precision mean that laser cutting service will only become more popular in the future, especially for companies that value both quality and quick turnaround times.

How Laser Cutting Is Taking CNC to the Next Level

What makes laser cutting better than traditional cutting methods

Laser cutting has changed the way industries think about precision. Compared to older cutting methods like sawing or mechanical drilling, laser cutting is faster, cleaner, and more accurate. A laser cutting beam can create detailed patterns without touching the material directly, which means less wear and tear on the machine and smoother finishes.

This contactless cutting also means there’s less chance of material distortion. Whether you’re working with thin sheet metal or thick steel plates, laser cutting delivers consistent, professional results every time. That’s why it’s becoming a key feature in many cnc cutting machine setups today.

How laser cutting works with cnc cutting machine systems

Many modern cnc cutting machines now include laser cutting capabilities. In these systems, a computer controls the movement of the laser beam, ensuring exact cuts based on digital designs.

This combination of cnc cutting machine precision and laser cutting power allows businesses to take on more complex projects. Whether it’s engraving fine details or slicing through tough materials, the teamwork between cnc control and laser technology offers unmatched flexibility.

As laser technology keeps improving, it’s making cnc machines even more powerful and expanding what they can do for industries everywhere.

Smart Automation and CNC Cutting Machines

How smart technology is improving cnc cutting machine performance

Automation is making a huge difference in the world of cnc cutting machines. Today’s machines can adjust their settings automatically based on the material they’re cutting. Some can even detect problems, like tool wear or temperature changes, before they cause serious issues.

Software upgrades allow operators to control multiple cnc cutting machines from one location. This saves time, reduces errors, and speeds up production lines. With smart automation, even small businesses can run more efficiently without needing a big team.

Can AI and machine learning make cnc cutting even better?

The future of the cnc cutting machine looks even brighter with artificial intelligence (AI) and machine learning. These technologies can analyze thousands of cutting jobs and learn how to optimize settings for better results.

Imagine a cnc cutting machine that automatically chooses the best cutting speed, laser intensity, or path without human input. AI can also predict when maintenance is needed, reducing unexpected breakdowns. This smart learning is set to make cnc cutting machines more reliable, faster, and smarter than ever.

What to Expect From CNC Cutting Machine Technology in the Next 5 Years

Will cnc cutting machines get more affordable and easier to use?

Yes, big changes are coming. As technology advances, cnc cutting machines are becoming more affordable and user-friendly. Small businesses and even hobbyists are starting to get access to high-quality cnc tools without breaking the bank.

User interfaces are getting simpler too. Newer machines often have touchscreen controls, guided tutorials, and easy file uploads, making them less intimidating for first-time users.

With better designs and lower costs, more people will be able to enjoy the power of cnc cutting machines in the next few years.

What industries will benefit most from new cnc cutting technology?

Many industries will see huge benefits. Cnc sheet metal fabrication companies will be able to produce complex parts faster and with less waste. Businesses offering laser cutting service will complete more jobs with even finer detail and higher customer satisfaction.

Construction, automotive, aerospace, and even fashion industries will continue to push the limits of what laser cutting and cnc cutting machine systems can achieve. The next five years promise smarter, faster, and greener manufacturing for everyone involved.