For startups, getting products made quickly and on budget is a top priority, That’s where cnc cutting services needed. CNC (Computer Numerical Control) machines cut with amazing precision and speed, helping new businesses create parts or products without big delays.

Since these services are highly automated, labor costs are lower too. This makes cnc cutting services a cost-friendly choice for startups looking to keep expenses down while still getting high-quality results.

The role of cnc cutting services in bringing ideas to life

Every new business starts with an idea, but turning that idea into a real product can be tricky. Cnc cutting services make this process easier by helping you create precise parts from your designs. Whether you’re building a simple prototype or a more complex product, CNC machines can handle it all.

For startups in industries like tech, design, or manufacturing, cnc cutting services are a fast way to bring ideas off the page and into the real world.

Custom Prototyping Made Easy with CNC Cutting Machine

Turning sketches into real products quickly

Need a prototype fast? A cnc cutting machine is your best friend. It takes your digital design and turns it into a finished piece with high accuracy. You can test your idea, spot any changes needed, and get a feel for the final product—often in just a few days.

This speed is perfect for startups that need to move quickly, especially when working with tight deadlines or pitching to investors.

Why a cnc cutting machine is perfect for precise prototypes

Prototypes need to be exact so you can see how your final product will look and function. A cnc cutting machine delivers that precision every time. Whether it’s a simple bracket or a detailed housing, you get clean cuts and smooth edges.

Plus, CNC technology is flexible—it works with many materials like metal, plastic, and wood. This gives startups the freedom to experiment and improve their designs easily.

Small Batch Production for Growing Businesses

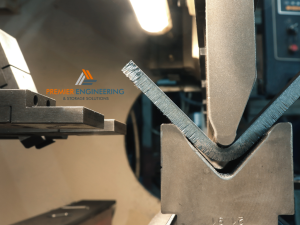

Using cnc sheet metal fabrication for limited runs

Once your prototype is ready, you may need a small production run to test the market or fill early orders. Cnc sheet metal fabrication is a great choice for these small batches. CNC machines can produce short runs efficiently, saving you the cost of setting up expensive, large-scale production.

At this stage, startups can tweak designs between batches, allowing you to perfect your product without wasting time or materials.

Flexibility to scale production as demand increases

One of the best things about cnc sheet metal fabrication is how easily it scales. As your business grows and demand rises, you can increase your order size without needing a full production overhaul. CNC machines handle small and large batches with the same precision.

So whether you’re making 10 pieces or 1,000, cnc cutting services grow with your business—giving you the flexibility and control you need at every stage.

Saving Time and Money Compared to Traditional Methods

How cnc cutting services reduce material waste

One big advantage of using cnc cutting services is how precise they are. This precision means less waste. Traditional cutting methods often result in extra scrap, but CNC machines cut only what’s needed with exact measurements.

For startups watching every dollar, this is a huge plus. Less waste means more savings—and a greener way to produce your products too.

Why automation lowers costs for startups

Because cnc cutting services are automated, there’s less need for manual labor. That keeps costs lower and reduces the chance of human error. Once your design is loaded, the machine does the rest—fast and accurately.

This is great news for small businesses that want reliable results without spending a fortune. By choosing CNC, you get high-quality cuts at a fraction of the traditional cost.

Laser Cutting vs CNC Cutting: What’s Best for Your Business?

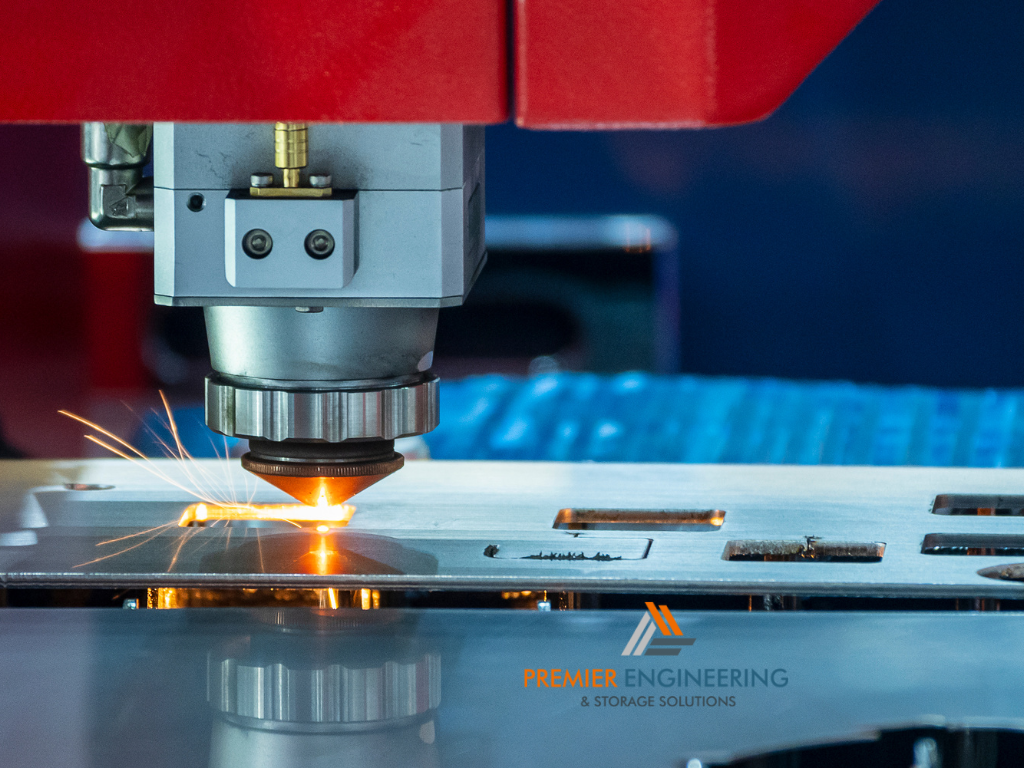

Understanding the differences in process and finish

Both laser cutting and CNC cutting have their place, but they work in different ways. Laser cutting uses a focused beam of light to slice through materials, offering super clean and smooth edges. It’s great for thinner materials and detailed designs.

Cnc cutting services, on the other hand, use physical tools like blades and bits. This makes CNC better for thicker materials or jobs that need shaping and drilling along with cutting.

When to choose laser cutting over cnc cutting services

If your project involves fine details, especially in thin sheets of metal or acrylic, laser cutting might be the better option. But for most startup projects—especially those needing strong, durable parts—cnc cutting services are usually the top pick.

Not sure which is right? A good provider will help you decide based on your design, material, and budget.

Partnering with the Right CNC Cutting Provider for Long-Term Success

What to look for in a cnc sheet metal fabrication partner

Finding the right partner is key for long-term success. Look for a company that offers both cnc cutting services and cnc sheet metal fabrication. This gives you flexibility as your business grows. Check for good communication, fast turnaround times, and a clear understanding of your needs.

Also, make sure they work with a variety of materials and can handle both small and large orders.

Building a relationship that grows with your business

The best partnerships are built on trust. When you find a reliable CNC provider, you get more than just cutting services—you gain a team that supports your growth. As your orders increase or your designs change, a good provider will adapt with you.

Choosing the right CNC partner means you can focus on growing your business, knowing your production is in expert hands.