Cold storage environments present unique challenges that demand specialized shelving solutions. These settings, crucial for preserving perishable goods, require shelving that can withstand low temperatures and humidity levels without compromising the integrity of stored products. The right industrial shelving units not only enhance operational efficiency but also play a pivotal role in maintaining product quality and safety. Selecting the appropriate shelving is therefore essential for businesses looking to optimize their cold storage spaces.

Understanding Cold Storage Needs

Temperature Considerations

The cold temperatures characteristic of these environments can significantly impact the durability and functionality of shelving materials. It’s crucial that the selected industrial shelving units maintain their structural integrity and do not become brittle in cold conditions, ensuring long-term reliability and safety.

Space Optimization

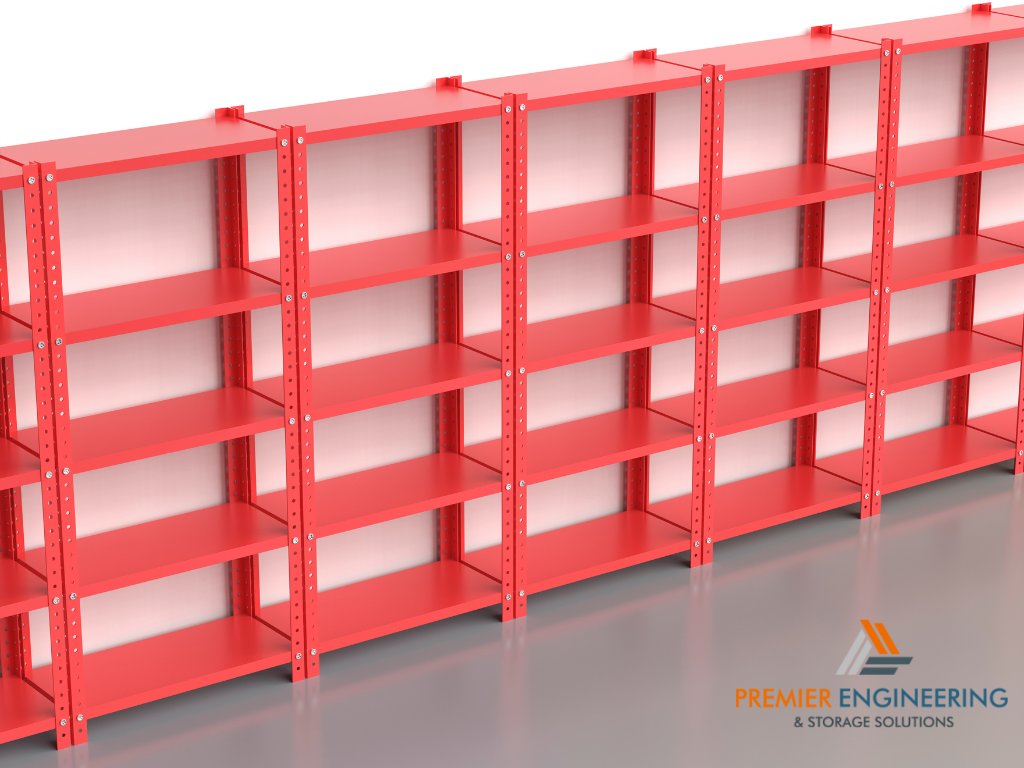

Maximizing storage space is especially important in cold storage environments, where the cost per square foot is higher due to refrigeration expenses. Efficiently designed shelving units that offer maximum storage capacity while allowing for optimal air circulation are essential for keeping products at the right temperature and reducing energy costs.

Material Selection for Cold Storage Shelving

Metal vs. Polymer

Choosing between metal and polymer shelving involves considering the specific needs and conditions of the cold storage environment. Metal shelving, often made from steel, is durable and capable of supporting heavy loads, but it requires a finish that prevents rust and corrosion. Polymer shelving, on the other hand, naturally resists corrosion and is easier to clean, making it a popular choice for environments with strict hygiene standards. However, its load-bearing capacity may be lower than that of metal shelving.

Corrosion Resistance

The importance of corrosion resistance in cold storage shelving cannot be overstated. Humidity levels in refrigerated and freezer spaces can lead to rust and corrosion in susceptible materials. Selecting shelving with corrosion-resistant coatings or materials is crucial to prevent contamination, ensure the longevity of the shelving units, and maintain a sanitary storage environment.

Design Features for Cold Storage

Ventilation and Airflow

Proper ventilation and airflow are crucial in cold storage environments to maintain consistent temperatures and ensure the quality of stored items. Industrial shelving units designed for cold storage should facilitate good air circulation around products. This can be achieved through open shelving designs, perforated shelves, or strategically placed gaps that allow cold air to pass freely, preventing cold spots and ensuring uniform temperature distribution.

Accessibility and Ergonomics

Efficient retrieval and stocking are essential for maintaining productivity in cold storage areas. Shelving units must be designed with ergonomics in mind, allowing workers to easily access items without unnecessary strain or exposure to cold temperatures. Considerations include adjustable shelf heights to accommodate different product sizes, easily movable units for flexible storage configurations, and the use of ergonomic tools and accessories that minimize the physical effort required by staff.

Insulation and Energy Efficiency

Reducing Thermal Exchange

Minimizing energy loss is vital for the economic operation of cold storage facilities. While shelving units themselves are not typically insulated, their design can contribute to reducing thermal exchange. Selecting materials that do not easily conduct heat and configuring shelving layouts to enhance the efficiency of cooling systems can play a significant role in maintaining desired temperatures with lower energy consumption.

Energy-efficient Practices

Adopting energy-efficient practices in cold storage operations includes the strategic placement of shelving units to optimize airflow and cooling efficiency. Utilizing reflective materials or coatings on shelving can also help reduce heat absorption. Implementing smart storage solutions, like automated retrieval systems, minimizes the frequency and duration of door openings, further conserving energy.

Safety and Compliance in Cold Storage

Load Capacity

Safety in cold storage environments extends to ensuring that shelving units can securely support the weight of stored goods. Overloading shelves can lead to structural failure, posing significant risks to workers and products. It’s crucial to select shelving units with appropriate load capacities for the items being stored and to regularly inspect them for signs of wear or damage that could compromise their integrity.

Health and Safety Standards

Compliance with health and safety standards is non-negotiable in cold storage operations. This includes adhering to regulations that govern the safe storage of food, pharmaceuticals, and other sensitive products. Industrial shelving units must be constructed from materials that are easy to clean and resistant to contamination. Facilities must also ensure that storage practices do not impede emergency access or egress, and that shelving installations comply with local fire codes and occupational safety regulations.

Innovations in Cold Storage Shelving

Automated Storage Solutions

The integration of automated storage solutions in cold storage shelving represents a significant advancement in warehouse management. These systems, including automated retrieval and storage systems (ASRS), provide numerous benefits such as enhanced space utilization, reduced energy consumption, and minimized human exposure to cold environments. By automating the movement of goods to and from the storage areas, businesses can achieve faster retrieval times, improve inventory accuracy, and lower labor costs associated with manual handling.

Smart Monitoring Systems

Incorporating smart monitoring systems into cold storage shelving allows for the real-time tracking of temperature and storage conditions. Sensors and IoT (Internet of Things) technologies can continuously monitor environmental parameters, ensuring that products are stored under optimal conditions. Alerts can be configured to notify managers of any deviations from set thresholds, enabling quick corrective actions to prevent spoilage or damage to sensitive goods.

Maintenance and Durability

Routine Maintenance Tips

To ensure the longevity and functionality of cold storage shelving, routine maintenance is essential. This includes regular inspections for signs of wear or damage, cleaning to prevent the buildup of ice or debris that can impede airflow, and checking for corrosion or structural integrity issues. Proper maintenance practices not only extend the lifespan of shelving units but also help maintain a safe working environment for employees.

Long-term Durability

Selecting shelving solutions that can withstand the rigors of cold storage environments over the long term is crucial. This involves choosing materials and finishes that are resistant to corrosion, capable of bearing the load requirements without deformation, and unaffected by extreme temperatures. Investing in high-quality, durable shelving systems minimizes the need for frequent replacements and repairs, offering better returns on investment.

Conclusion

In essence, the effective planning and outfitting of cold storage facilities with the appropriate industrial shelving units are instrumental in maintaining product integrity, ensuring worker safety, and achieving operational excellence. As the industry continues to evolve, staying informed about the latest trends and advancements will be key to making informed decisions that enhance the efficiency and sustainability of cold storage solutions.

1 comment