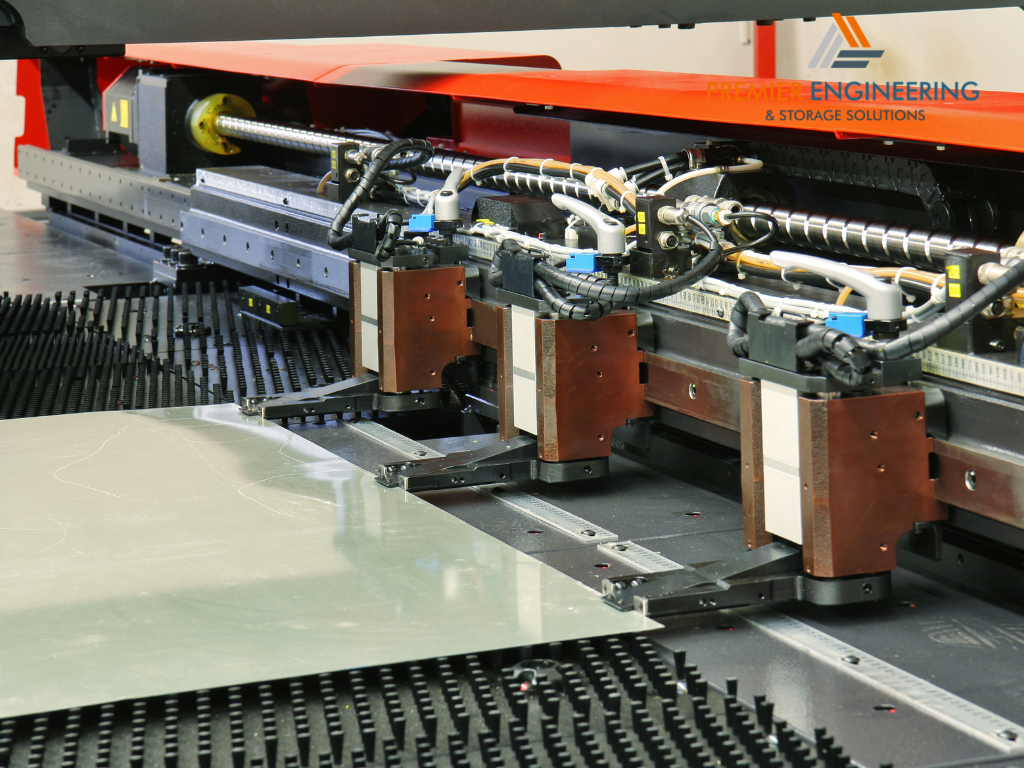

CNC punching service is a manufacturing process that uses a machine to punch holes or shapes into sheet metal. This process is highly automated and controlled by a computer, which directs the machine to follow precise patterns based on the design input. CNC punching is essential in modern manufacturing because it allows for high precision, consistency, and efficiency in producing complex parts or components. The process is versatile, handling various materials such as aluminum, steel, and copper, making it a go-to solution for industries ranging from automotive to aerospace.

The Importance of Precision and Efficiency

In CNC punching, precision and efficiency are paramount. Precision ensures that every part produced meets exact specifications, which is critical for maintaining the quality and functionality of the final product. Even a slight deviation can lead to parts that don’t fit together correctly or fail to meet safety standards. Efficiency, on the other hand, refers to the machine’s ability to produce parts quickly without sacrificing quality. This is particularly important in high-volume production environments where time is money. By maximizing both precision and efficiency, CNC punching services help manufacturers reduce waste, lower production costs, and deliver products on time.

Collaborating Effectively with Turret Punching Services

What is Turret Punching and How Does it Differ from CNC Punching?

Turret punching is a specific type of CNC punching that uses a turret—a rotating drum with multiple punching tools attached—to perform a series of punches on the material. The primary difference between turret punching and standard CNC punching lies in the tool setup and the machine’s configuration. While CNC punching typically uses a single tool or a limited set of tools, turret punching can switch between different tools quickly, allowing for more complex and varied punching patterns in a single operation. This makes turret punching particularly useful for producing parts with multiple holes, shapes, or intricate designs.

Tips for Choosing the Right Turret Punching Services

Selecting the right turret punching services requires careful consideration of several factors:

- Material Compatibility: Ensure that the service provider can handle the type of material you need, whether it’s aluminum, stainless steel, or another metal.

- Project Complexity: Consider the complexity of your design. Turret punching is ideal for parts that require multiple operations, such as different hole sizes or shapes.

- Turnaround Time: Check the provider’s ability to meet your deadlines. High-volume projects may require a provider with advanced machinery capable of rapid production.

- Experience and Expertise: Look for a service provider with a proven track record in turret punching, particularly in your industry.

Leveraging CNC Cutting Services for Complex Projects

Integrating CNC Cutting with CNC Punching

For projects that require both cutting and punching, integrating CNC cutting services with CNC punching can be a highly effective approach. CNC cutting uses a computer-controlled machine to cut materials into precise shapes, often complementing the work done by a CNC punching machine. By combining these two processes, manufacturers can achieve more complex geometries and finer details that would be challenging with punching alone. This integration is particularly beneficial in industries that require intricate parts, such as aerospace or electronics, where precision and complexity are critical.

Maximizing Efficiency with Combined Services

When CNC cutting and punching services are combined, the overall production process becomes more streamlined. This efficiency comes from the ability to perform multiple operations in a single setup, reducing the need for multiple machines and handling. The result is a faster turnaround time and lower production costs. Additionally, combining these services can reduce material waste, as the cutting and punching can be optimized to make the best use of the material. This is particularly important in industries where material costs are high, and sustainability is a priority.

The Role of Laser Cutting in Enhancing CNC Punching Outcomes

Laser Cutting vs. CNC Punching: When to Use Each

Laser cutting and CNC punching are both widely used in manufacturing, but they serve different purposes depending on the project’s requirements. Laser cutting uses a high-powered laser to cut materials with extreme precision, making it ideal for intricate designs and tight tolerances. CNC punching, on the other hand, is better suited for creating holes or shapes in thicker materials where speed and durability are required. When deciding between the two, consider the material thickness, the complexity of the design, and the precision needed. For example, laser cutting is often preferred for thin materials or detailed patterns, while CNC punching is more efficient for thicker materials with simpler designs.

Integrating Laser Cutting with CNC Punching for Precision

In some cases, integrating laser cutting with CNC punching can offer the best of both worlds. By using laser cutting for detailed areas and CNC punching for the more straightforward, structural elements, manufacturers can achieve a high level of precision and efficiency. This combination is especially useful in applications where both intricate design and structural integrity are required, such as in the automotive or aerospace industries. By strategically integrating these two processes, manufacturers can produce parts that meet exact specifications without compromising on speed or quality.

Understanding Material Considerations for CNC Punching and Cutting

Choosing the Right Materials for CNC Punching

Selecting the appropriate material is crucial for the success of CNC punching. The material’s thickness, hardness, and malleability directly influence the punching process. For instance, softer metals like aluminum and copper are easier to punch and form, while harder materials like stainless steel require more force and specialized tooling. When choosing a material, it’s essential to consider not only the end-use of the product but also how the material will behave during the punching process. The right material choice ensures that the punched parts meet the desired specifications without causing excessive wear on the machinery.

How Material Choice Affects Turret Punching and CNC Cutting

The material selected for a project also impacts the effectiveness of both turret punching and CNC cutting services. For turret punching, the material’s thickness and hardness determine the types of tools that can be used and the speed at which the process can be completed. Similarly, in CNC cutting, materials that are too thick or hard can slow down the cutting process and increase tool wear. By carefully selecting materials that are compatible with both punching and cutting processes, manufacturers can achieve higher efficiency, reduce waste, and produce parts that meet stringent quality standards.

Optimizing Design for CNC Punching Efficiency

Design Tips for Cost-Effective CNC Punching

Designing parts that are optimized for CNC punching can significantly reduce production costs and improve efficiency. To achieve cost-effective CNC punching service, it’s important to minimize complex shapes that require multiple punches, avoid sharp internal corners that can cause tool wear, and design with standard tooling sizes in mind. Additionally, using CAD software to simulate the punching process can help identify potential issues before production begins, saving time and reducing the risk of errors. By following these design tips, businesses can ensure that their parts are both functional and economical to produce.

Balancing Complexity with Practicality in CNC Designs

While complex designs can offer unique features and functionalities, they also present challenges in the CNC punching process. It’s important to strike a balance between design complexity and practicality. For instance, intricate designs might require special tooling or slower production speeds, which can drive up costs. Simplifying certain elements of the design without sacrificing functionality can make the CNC punching process more efficient and cost-effective. This balance ensures that the final product meets both aesthetic and practical needs while remaining within budget.

Quality Control in CNC Punching and Cutting Services

Ensuring Precision Through Rigorous Quality Checks

Quality control is a critical component of CNC punching and cutting services. Precision is paramount, and even the smallest deviation can lead to parts that are out of specification. Rigorous quality checks, including dimensional inspections, material testing, and visual inspections, are essential to ensure that every part meets the required standards. By implementing a robust quality control process, manufacturers can detect and correct any issues early in the production cycle, preventing costly rework and ensuring customer satisfaction.

The Role of Technology in Quality Assurance

Advancements in technology have greatly enhanced the quality assurance process in CNC punching and cutting services. Automated inspection tools, such as laser measurement systems and coordinate measuring machines (CMMs), allow for high-precision checks that are faster and more accurate than manual inspections. These tools can detect even the slightest deviations from the design specifications, ensuring that each part meets the highest quality standards. By leveraging these technologies, manufacturers can maintain consistent quality, reduce scrap rates, and improve overall efficiency.

Maximizing the Benefits of CNC Punching and Related Services

Recap of Key Strategies for Effective CNC Punching

To maximize the benefits of CNC punching services, it’s important to focus on several key strategies. First, choose the right materials that align with the punching and cutting processes. Next, optimize your designs to reduce complexity and production costs. Finally, implement rigorous quality control measures to ensure that every part meets the highest standards. By following these strategies, businesses can enhance their production processes, reduce waste, and achieve greater overall efficiency.

Final Thoughts on Enhancing Your Production Process

Continuous improvement is key to staying competitive in today’s manufacturing landscape. By exploring new technologies and methodologies, such as integrating laser cutting with CNC punching or leveraging advanced quality control tools, businesses can further enhance their production processes. Staying ahead of the curve in terms of efficiency, quality, and innovation will ensure long-term success in an increasingly demanding market.