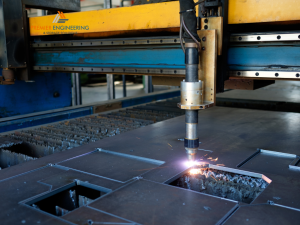

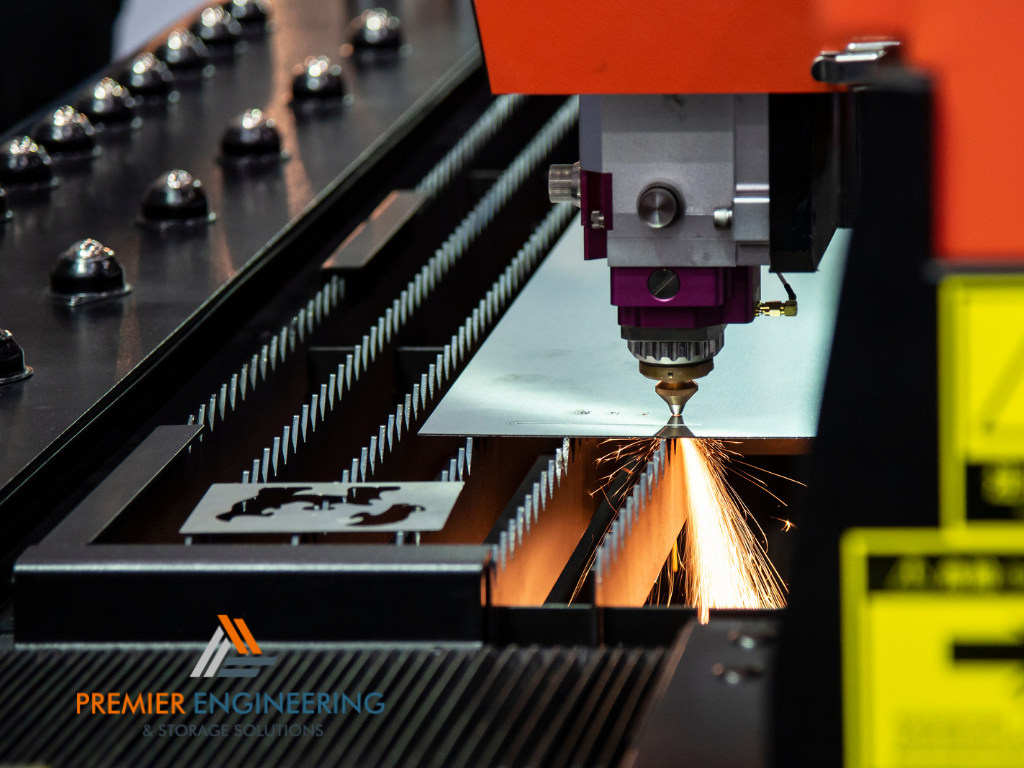

Proper preparation is the foundation of successful CNC cutting services. Whether you’re working on a project for laser cutting, steel metal cutting, or sheet metal manufacturing, a well-prepared design ensures precision and efficiency.

By investing time in preparing your files and materials, you can save money, reduce waste, and achieve top-quality results. Well-prepared designs also make the process smoother for the laser cutting service, helping you get the desired outcome faster.

What Are the Essential Steps to Start Your CNC Design?

Understanding the Basics of CNC Design Files

CNC cutting relies heavily on the accuracy of your design files. Most machines work with specific file types like DXF, DWG, or AI, as these formats allow for precise cutting paths. These files communicate the dimensions and shapes to the CNC machine, ensuring accurate cuts.

If you’re not familiar with creating these file types, many design software programs offer templates specifically for CNC cutting services. Getting your design into the correct format is one of the most important steps in preparing for cutting.

Choosing the Right Material for Your Project

Your material choice directly impacts the cutting process and final product. For projects requiring durability, steel metal cutting is an excellent option. For intricate designs, lightweight materials like aluminium or plastic may be more suitable.

When preparing for sheet metal manufacturing, consider factors such as thickness, finish, and project requirements. Consulting your laser cutting service provider can help you choose the best material for your design and intended use.

How to Optimise Your Design for Precision Cutting?

Simplifying Your Design for Efficiency

Complex designs may look impressive, but they can increase production time and costs. Simplifying your design while maintaining its functionality is a great way to achieve efficient and precise cuts.

Avoid unnecessary details or excessive curves that can complicate the cutting process. Clean, straightforward designs are easier for CNC cutting services to execute with accuracy.

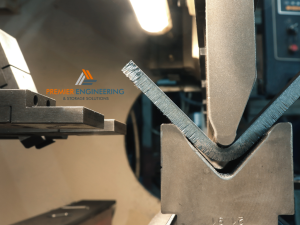

Allowing for Material Thickness and Tolerances

Material thickness plays a key role in creating accurate cuts. Whether you’re working on steel metal cutting or sheet metal manufacturing, your design must account for the material’s dimensions.

Adding tolerances—small allowances for material expansion or contraction—ensures that the final product fits together perfectly, especially in multi-part assemblies. Always consult your laser cutting service provider for guidance on material-specific tolerances.

Why File Formats Matter for CNC Cutting Services?

Common File Types Accepted by Laser Cutting Machines

Not all file formats work with every CNC machine. The most commonly accepted formats for laser cutting include SVG, EPS, DXF, and CAD files. These formats ensure the machine can accurately follow the cutting paths defined in your design.

Before submitting your project, confirm the required file format with your laser cutting service provider. This step avoids delays and ensures the process runs smoothly.

How to Convert or Export Your Design to the Right Format

If your design isn’t in the required format, don’t worry—most design software allows you to export files into compatible formats. For instance, Adobe Illustrator files can easily be converted into DXF or SVG files suitable for CNC cutting services.

Always double-check the exported file to ensure that no details were lost during conversion. This simple step can save time and ensure your design is ready for cutting.

How to Ensure Your Design is Compatible with Laser Cutting?

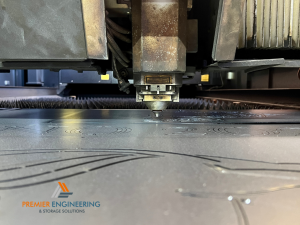

Avoiding Overlapping Lines and Open Paths

Overlapping lines or open paths in your design can confuse CNC machines, leading to errors or incomplete cuts. Carefully review your design to eliminate any redundant or overlapping elements.

For precise laser cutting, make sure all paths are closed. This ensures the cutting machine can follow the design accurately, resulting in clean, professional cuts.

What Role Do Material Properties Play in CNC Design?

Understanding Material Limitations for Steel Metal Cutting

When working on projects involving steel metal cutting, it’s essential to understand the material’s properties. Factors like hardness, thickness, and heat resistance can affect the cutting process. For instance, thicker steel requires more powerful cutting tools and precise settings to ensure clean cuts.

Heat resistance is another important consideration. Steel can heat up during cutting, which might affect the edges if not managed properly. Knowing these limitations helps you choose the right cutting method and settings, ensuring a high-quality result.

Selecting the Right Material for Sheet Metal Manufacturing

Choosing the right material for sheet metal manufacturing is a balancing act. Durability, cost, and finish are key factors to consider. For instance, aluminium is lightweight and cost-effective but may not be as strong as steel for heavy-duty applications. Stainless steel, on the other hand, offers excellent durability and a polished finish but comes at a higher price.

The intended use of the product will guide your material choice. Always consult with your laser cutting service provider to select the most suitable material for your design and budget.

How to Add Text or Patterns to Your CNC Design?

Adjusting Font Sizes and Line Weights for Laser Cutting

Adding text or patterns to your CNC design can enhance its functionality or aesthetics, but it’s important to ensure they’re legible and precise. For text, use clean, simple fonts with appropriate spacing and line thickness. Thin lines or small fonts may not cut properly, especially in laser cutting processes.

Always test your design with a mock-up or digital preview to ensure readability. Adjusting font sizes and line weights before submitting your design ensures smooth execution and avoids costly mistakes.

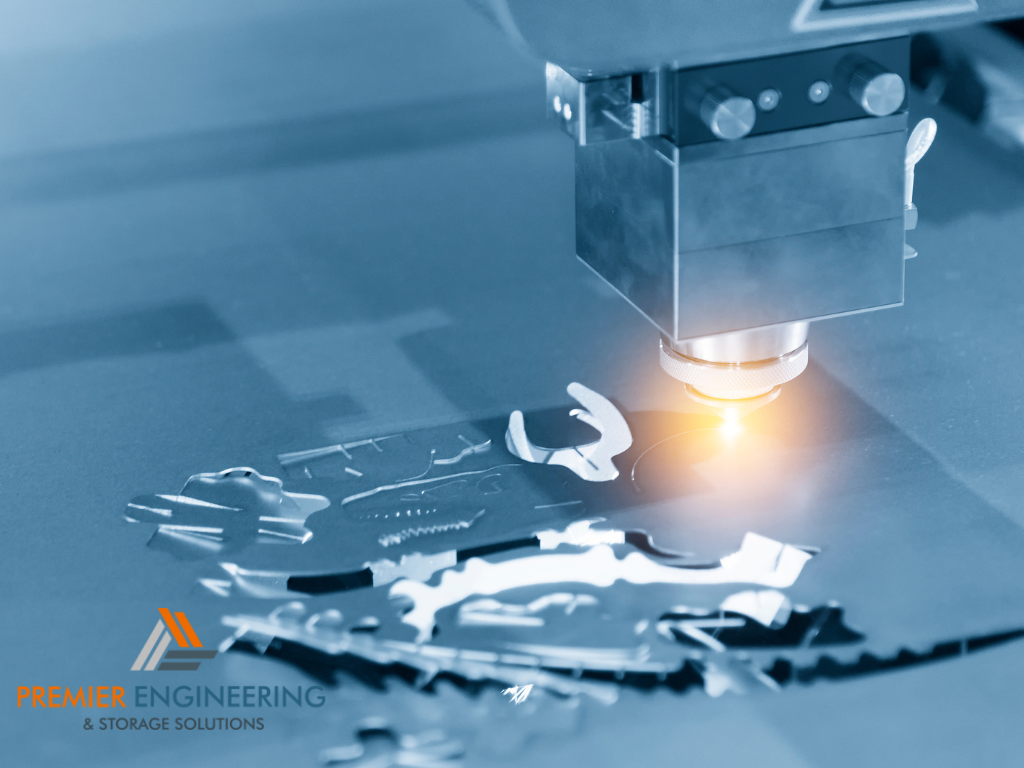

Creating Decorative Patterns with Precision

Decorative patterns can add a unique touch to your project, whether for branding, aesthetics, or functionality. For laser cutting tools, designs with sharp corners, clear paths, and consistent spacing work best.

Use software to ensure patterns are symmetrical and don’t overlap, as this could confuse the cutting machine. By fine-tuning your patterns and keeping them compatible with CNC cutting services, you can achieve flawless decorative elements.

How to Work with a Laser Cutting Service to Finalise Your Design?

Sharing Your Design and Specifications

To get the best results, provide your laser cutting service with detailed specifications. This includes the type of material, desired thickness, finish preferences, and any tolerances for fitting. A clear, detailed file ensures that the service provider understands your vision and executes it accurately.

Double-check your file format and ensure it’s compatible with their machinery (e.g., DXF, DWG, or SVG). The more information you provide, the smoother the process will be.

Collaborating with Experts to Perfect Your Design

Working with professionals in CNC cutting services can significantly improve your design. They can offer insights into optimising your file, selecting the right material, and choosing the best cutting method.

Don’t hesitate to ask for feedback or suggestions. Experienced providers can spot potential issues and recommend adjustments that enhance the final product, whether it’s for steel metal cutting or sheet metal manufacturing. Collaboration ensures that your design moves from concept to reality seamlessly.

Perfect Designs for Perfect CNC Cuts

Recap the Importance of Design Preparation

Preparing your design carefully is the key to achieving precision and quality in CNC cutting services. From selecting the right file format to choosing appropriate materials for laser cutting or sheet metal manufacturing, every detail matters.

Proper preparation not only enhances the outcome but also saves time and reduces costs. By investing in the preparation phase, you can avoid errors and achieve flawless results.

Partner with Experts for the Best Results

Collaborating with a trusted laser cutting service ensures that your designs are executed to perfection. Experienced professionals can bring your ideas to life, whether you’re working on steel metal cutting projects or intricate decorative patterns.

With thoughtful preparation and expert guidance, achieving exceptional results has never been easier. Start your CNC cutting journey today and turn your designs into high-quality, finished products!