Have you ever wondered how big companies produce thousands, even millions of items, consistently and with precision? One of the secrets lies in a powerful technology called laser cutting. It’s revolutionizing the world of manufacturing, making it possible to shape and customize materials like never before.

Have you ever wondered how big companies produce thousands, even millions of items, consistently and with precision? One of the secrets lies in a powerful technology called laser cutting. It’s revolutionizing the world of manufacturing, making it possible to shape and customize materials like never before.

The Basics of Laser Cutting

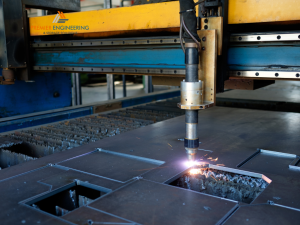

Now, what is laser cutting? It’s a technology that uses a high-power laser to cut or engrave materials. Think of it as a super-accurate, extremely powerful version of the scissors you might use in art class. With laser cutting service, large companies can easily slice through tough materials, like steel, to create parts for a vast range of products.

Laser Cutting in Steel Metal Fabrications

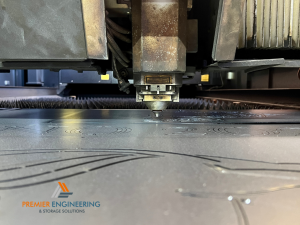

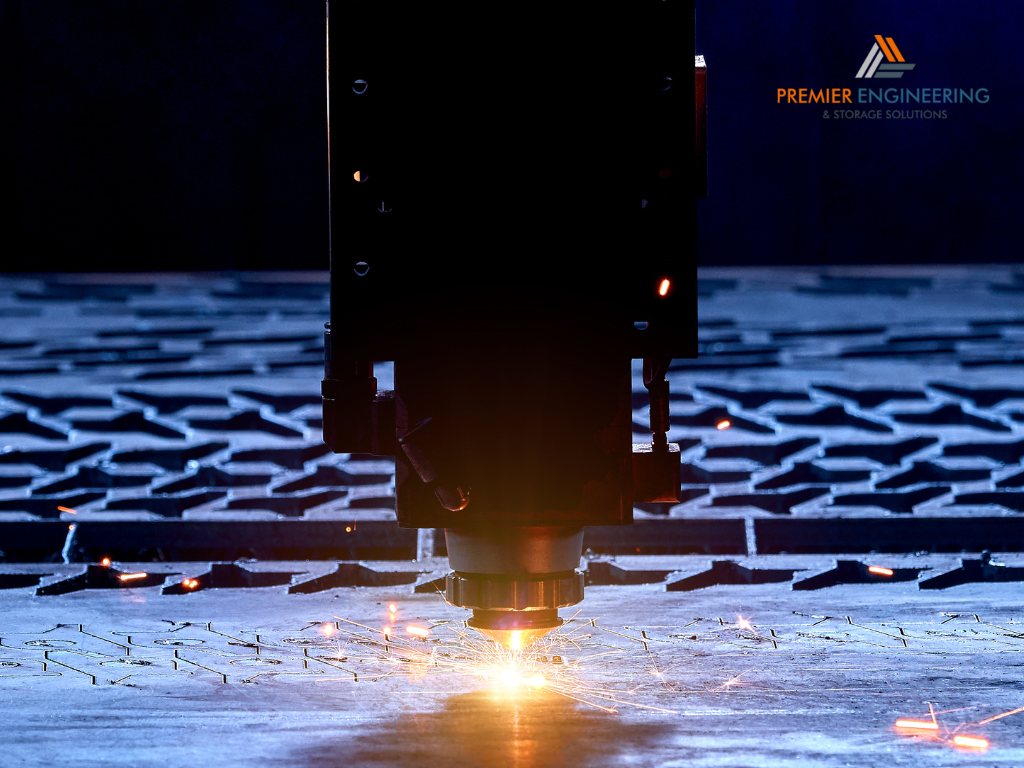

Speaking of steel, laser cutting plays a crucial role in steel metal fabrications. Here’s how it works. Steel laser cutting services use a focused beam to melt, burn, or vaporize the steel, producing a clean, precise cut. They can even create intricate shapes and patterns on a stainless-steel splash back, adding both functionality and aesthetic appeal.

The Role of Laser Cutting in Sheet Metal Manufacturing

But it’s not just about steel. Laser cutting also plays a pivotal role in sheet metal manufacturing. For example, it’s used to create the shelves for shelving units, the doors for metal storage cabinets, and even the surface of your workbench. So next time you see a beautifully crafted piece of sheet metal, chances are, laser cutting had a role in its creation.

CNC Cutting Services and Laser Cutting

But wait, you might ask, what about CNC cutting services and CNC punching service? Well, CNC (Computer Numerical Control) is an umbrella term that covers several techniques, including laser cutting. It’s a method where computer-controlled machines, like laser cutters, perform tasks with accuracy that humans simply can’t match.

Laser Cutting versus Traditional Methods

Compared to traditional methods, laser cutting has clear advantages. For example, imagine trying to cut a precise pattern into steel using manual methods. It would be incredibly time-consuming and prone to errors. On the other hand, laser cutting can complete the task quickly, with exceptional precision.

Laser Cutting and Workspace Efficiency

So, how does all of this tie into your workspace? Consider your workbench, shelving units, and storage cabinets. These items are all products of manufacturing processes, possibly involving laser cutting. For instance, your metal storage cabinet and industrial shelving units could have been cut and shaped using laser cutting technology.

Welding Services in Sydney and the Role of Laser Cutting

Even welding services in Sydney and elsewhere often utilize laser cutting in their operations. It’s a tool that enables them to deliver precision work, whether they’re creating a complex industrial structure or a simple stainless-steel splash back.

From Query to Clarity: The Role of Laser Cutting in Manufacturing

Now that we’ve explored the basics of laser cutting and its role in manufacturing, let’s answer some of the questions you might be pondering.

1. What are the key advantages of laser cutting compared to traditional manufacturing methods?

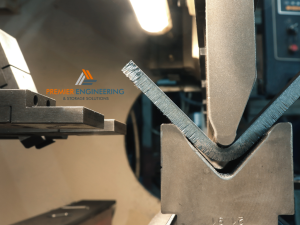

Excellent question! Laser cutting holds many advantages over traditional methods. Firstly, it’s incredibly precise. It can make intricate cuts that are too complex for conventional methods. Secondly, it’s efficient.

A company like Premier Engineering can cut numerous pieces in a short amount of time, maximizing productivity. Finally, laser cutting doesn’t involve direct contact with the material, reducing the risk of material deformation.

2. How does CNC technology, including CNC cutting services and CNC punching service, integrate with laser cutting in manufacturing processes?

CNC technology and laser cutting are complementary. CNC refers to a computer’s ability to control a manufacturing process. In a setup like at Premier Engineering, CNC technology directs the laser cutter, guiding it to make precise cuts or punches. So, in essence, CNC technology forms the brain, while the laser cutter serves as the hands, executing the actual task.

3. In what ways is laser cutting used in creating common items in a workspace, like workbenches and storage cabinets?

You’d be surprised at how much of your workspace owes its existence to laser cutting! Take your workbench, for instance. The smooth metal surface could have been cut and shaped using a laser. Similarly, the precisely cut shelves in your storage cabinets, and the neatly done corners of your metal storage cabinet, are likely the result of laser cutting. This technology plays a significant role in shaping the world around us, often in ways we don’t even realize.

In conclusion, laser cutting is more than just a manufacturing process; it’s an integral part of how we create, shape, and innovate. It’s in the products we use daily, the spaces we inhabit, and the progress we make.

With companies like Premier Engineering at the forefront, laser cutting is set to revolutionize manufacturing further, making it faster, cleaner, and more efficient. And who knows? The next time you see a perfectly cut piece of metal, you might just appreciate the marvel of laser cutting a little more!