Storage solutions play a critical role in organizing our commercial spaces. Among the various types of storage options available, metal shelves, industrial shelving, and metal storage cabinets stand out for their durability and strength. But have you ever wondered how these storage cabinets and shelving units are made? The answer lies in welding and fabrication services.

Storage solutions play a critical role in organizing our commercial spaces. Among the various types of storage options available, metal shelves, industrial shelving, and metal storage cabinets stand out for their durability and strength. But have you ever wondered how these storage cabinets and shelving units are made? The answer lies in welding and fabrication services.

Welding and Fabrication: The Birth of Commercial Shelves

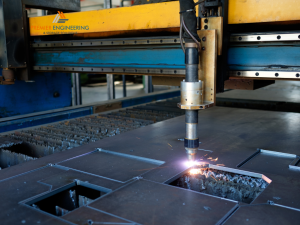

Welding and fabrication are integral parts of creating sturdy and reliable commercial shelves. Through a combination of precision engineering services and mechanical engineering solutions, pieces of metal are transformed into functional shelving units.

First, let’s understand what welding is. Simply put, welding is a process where two pieces of metal are joined together using heat or pressure. Now, how does this fit into creating commercial shelves? Well, in a metal fabrication workshop, welding is used to join various parts of a shelf together.

The Role of CNC Machining Services in Shelf Production

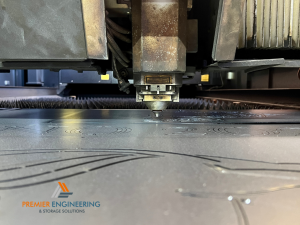

The manufacturing of commercial shelves isn’t just about welding pieces together. It’s a lot more intricate. Here is where CNC machining services come into play. CNC, or Computer Numerical Control, is a process used in manufacturing where pre-programmed computer software dictates the movement of machinery. In the case of shelf production, CNC machines help cut and shape metal parts with high precision.

CNC machining services offer more than just accuracy. They also increase efficiency and consistency, making them vital for metal manufacturing services producing large volumes of shelving units.

Custom Metal Fabrication: Meeting Unique Storage Needs

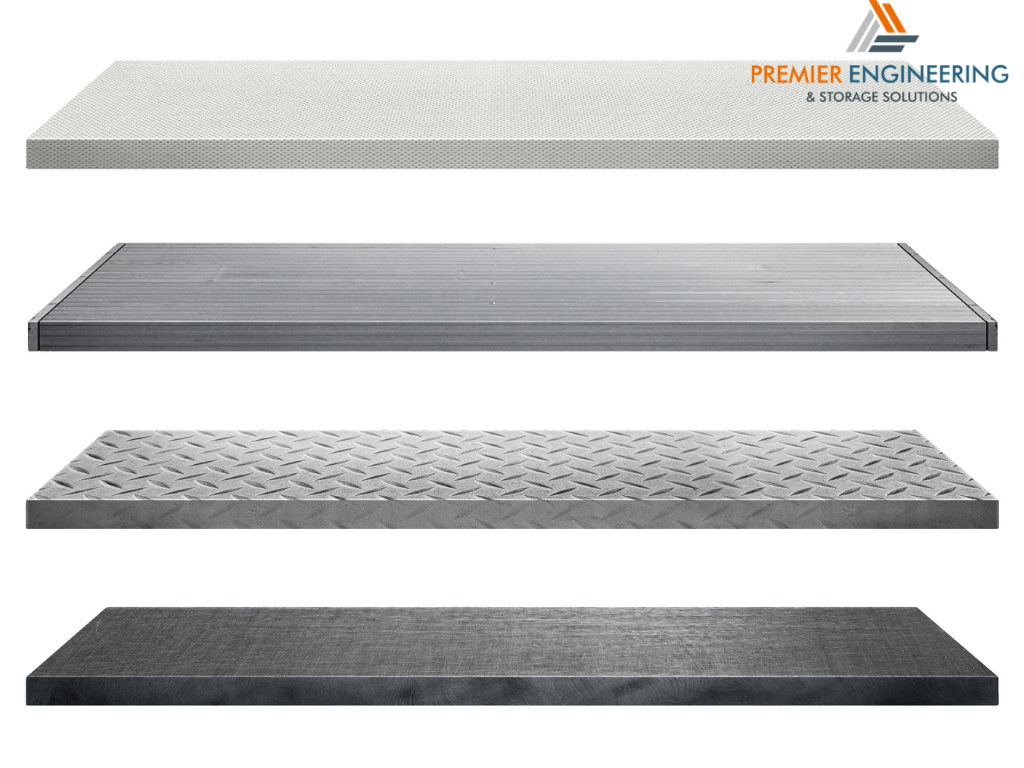

While off-the-shelf storage solutions work for some, many businesses have unique requirements. This is where custom metal fabrication shines. Whether it’s creating industrial shelves for a warehouse or tailor-made storage cabinets for a retail store, custom metal fabrication allows for the design and production of storage solutions to fit specific needs.

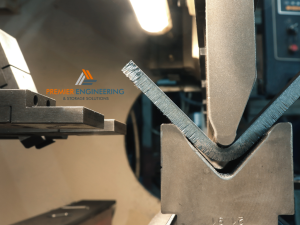

Sheet metal fabrication companies often employ a machined components supplier who uses advanced tools and techniques to cut, bend, and assemble metal into customized shelving units.

The Significance of Welding and Fabrication Services

The journey of a piece of metal to becoming a part of your storage solution is fascinating. From welding and fabrication services in the workshop to the use of CNC machining services for precision, a lot goes into creating robust metal shelves and storage cabinets.

Through custom metal fabrication, these solutions can be tailored to meet the specific needs of businesses. So, the next time you see a shelving unit, you’ll know the intricate processes and engineering solutions behind its creation. Remember, effective storage solutions are not just about organizing space; they’re about engineering space to work for you.

Digging Deeper on Storage Solutions

Now that we’ve shed some light on how commercial shelves are made, let’s delve deeper into some of your burning questions.

Distinction Between Welding and Fabrication

You may wonder, “What are the key differences between welding and fabrication?” While these processes often work hand in hand, they are not the same. Fabrication is the overarching process of creating a metal product, which involves several steps, one of which is welding. Welding, as we’ve learned, is the process of joining two pieces of metal together.

Companies like Premier Engineering specialize in these processes, employing their expertise in precision engineering services to craft top-quality metal shelves and storage solutions.

The Role of CNC Machining in Efficiency and Accuracy

Another interesting query to explore is, “How does CNC machining contribute to the efficiency and accuracy of manufacturing industrial shelves and storage cabinets?” Well, the answer lies in the level of precision that CNC machining services provide.

When creating shelving units, accuracy is paramount. CNC machines, with their computer-guided machinery, help cut and shape metal components with high precision. This efficiency helps companies like Premier Engineering maintain a high level of quality across all their products, from commercial shelves to custom-built storage cabinets.

Considering Custom Metal Fabrication for Your Business

Finally, you might be asking, “What factors should I consider when seeking custom metal fabrication for my unique storage needs?” Well, every business is different, and so are its storage needs. Custom metal fabrication allows for the design and production of storage solutions tailored to your specifications.

When contemplating custom solutions, consider the space you have, the items you need to store, and the workflow of your operations. A reputable sheet metal fabrication company like Premier Engineering can guide you through this process, helping you design a solution that best fits your needs.

Remember, the journey to effective storage solutions is not just about finding a product that fits your space. It’s about finding a solution that fits your operations. It’s about understanding the intricate processes behind each shelving unit’s creation and appreciating the expertise and precision it took to engineer these vital components of your commercial space.