Introduction

Storage solutions play an integral role in organizing spaces, whether at home, the office, or in industrial settings. Among the myriad of options available in the market, metal storage cabinets stand out due to their robustness and longevity.

The key to their resilience lies not just in their metallic nature but also in the specific materials from which they are crafted. In this article, we delve deep into the common materials used in the manufacture of these cabinets and discuss why they’re such a sought-after choice.

Common Materials Used in Metal Storage Cabinets

Steel

Characteristics and Benefits of Steel Cabinets:

- Strength: Steel is renowned for its strength and durability. This means that steel cabinets can bear considerable weight, making them ideal for storing heavy items.

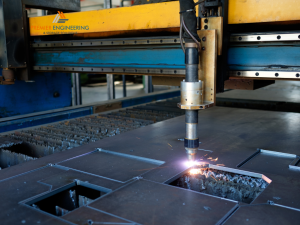

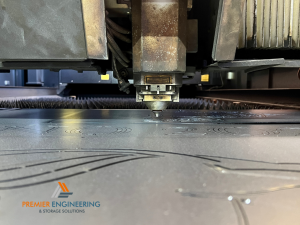

- Malleability: Despite its strength, steel is malleable, which allows for intricate designs and customizations tailored to specific storage needs.

- Cost-Efficiency: Steel cabinets offer a balance between quality and cost. They are relatively more affordable than some other materials while providing commendable durability.

Common Uses and Environments for Steel Cabinets:

- Offices: Filing cabinets, personal storage lockers, and stationary cabinets are often made of steel, providing security for documents and personal belongings.

- Industrial Settings: In factories and workshops, steel cabinets house tools, equipment, and other heavy machinery components.

- Garages and Workshops: The robustness of steel makes it apt for storing tools and equipment in garages and home workshops.

Stainless Steel

Why Stainless Steel is a Preferred Choice in Specific Settings:

- Corrosion Resistance: Unlike regular steel, stainless steel has a chromium layer that prevents rusting, making it perfect for environments where there’s a lot of moisture or exposure to chemicals.

- Hygienic Properties: Its non-porous surface makes it resistant to bacteria and easy to clean, which is why stainless steel cabinets are common in hospitals, labs, and kitchens.

Comparing Standard Steel vs. Stainless Steel:

- Cost: Stainless steel tends to be more expensive than standard steel due to the added benefits it offers in terms of corrosion resistance and hygiene.

- Maintenance: While both types require cleaning, stainless steel might need less frequent rigorous maintenance because of its resistance to rust and staining.

- Appearance: Stainless steel has a sleek, shiny finish which may be preferred for aesthetic reasons in certain settings like modern kitchens or upscale offices.

Aluminum

Lightweight Nature and Its Advantages:

- Mobility: Aluminum cabinets are easier to move because of their lightweight nature, making them apt for spaces that require rearranging or redecoration.

- Cooling Properties: Aluminum naturally dissipates heat faster, making it suitable for storing items that benefit from staying cool.

Instances Where Aluminum Might be the Chosen Material:

- Outdoor Settings: Aluminum’s rust-resistant properties make it ideal for outdoor storage solutions.

- Modern Home and Office Interiors: The sleek and modern appearance of aluminum cabinets complement contemporary design aesthetics.

In understanding the materials that make up metal storage cabinets, one can appreciate their inherent durability and versatility. Whether opting for the heft of steel, the hygiene of stainless steel, or the lightness of aluminum, there’s a metal cabinet tailored to meet specific needs and environments.

Rust and Corrosion Resistance

Rust and corrosion are two primary concerns when it comes to metal items, particularly those placed in environments exposed to moisture, humidity, or chemicals. The ability of a metal storage cabinet to resist these deteriorating processes significantly determines its longevity.

Protective Coatings

Many metal storage cabinets undergo treatments to enhance their resistance to environmental factors:

- Powder Coating: This is a popular treatment for steel cabinets. It’s a type of coating that’s applied as a free-flowing, dry powder and then cured under heat. This forms a skin that is harder and more durable than conventional paint, providing enhanced protection against rust.

- Galvanization: This process involves coating steel or iron with a layer of zinc. The zinc acts as a barrier against rust, ensuring the cabinet remains rust-free for a longer duration.

- Anodizing for Aluminum: Anodized aluminum has an increased resistance to corrosion. The process makes the surface harder, more durable, and less likely to scratch.

Maintenance Practices

Routine care can further extend the life of a metal storage cabinet:

- Regular Cleaning: Wiping down cabinets with a dry cloth removes dust and other contaminants that might hold moisture against the metal surface.

- Inspection: Periodically checking for scratches or exposed areas ensures early detection and rectification.

- Environment Control: If possible, controlling the humidity and moisture levels in the environment can prevent rust formation.

Weight Capacity and Structural Integrity

The value of a metal storage cabinet is not only in its ability to resist wear but also in its capacity to safely hold items without buckling or deforming.

Gauge of Metal

The thickness or gauge of the metal used in the cabinet largely determines its weight-bearing capacity. Thicker gauges tend to be sturdier.

| Metal Type | Common Gauges | Best For |

|---|---|---|

| Steel | 16-24 gauge | Heavy tools, machinery parts |

| Aluminum | 14-20 gauge | Lighter tools, personal items |

Reinforcements and Supports

Many metal cabinets come with additional supports, like:

- Shelving Reinforcements: These prevent shelves from sagging under weight.

- Corner Braces: They ensure the structural integrity of the cabinet is maintained even when moved or under duress.

Load Limit Recommendations

It’s essential to be aware of the manufacturer’s load limit recommendations:

- Even Distribution: Weight should be evenly distributed to prevent undue stress on any one part of the cabinet.

- Overloading Risks: Exceeding the recommended weight limits can compromise the cabinet’s integrity and safety.

The durability of metal storage cabinets is a result of meticulous design, quality materials, and proper maintenance. Whether it’s for personal use or professional needs, understanding the factors that contribute to their long-lasting nature helps users make informed decisions and ensure their metal cabinets stand the test of time.