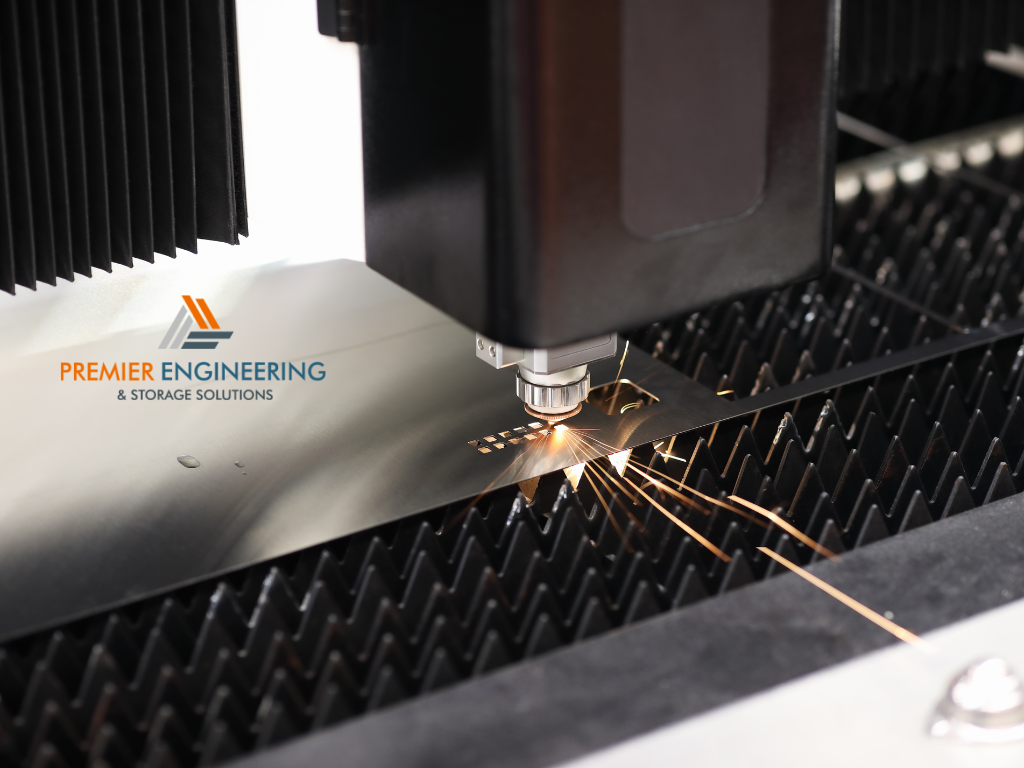

When engineers need to create a new part or test a design quickly, they often turn to a laser cutting service. Why? Because it saves time without cutting corners on quality. Unlike manual tools, lasers provide incredibly accurate cuts on a wide range of materials like metal, acrylic, or plastics.

Whether you’re working on a small prototype or a more complex build, the laser gets it done fast and clean. This means fewer delays and better results — especially when you’re developing new products or improving existing ones.

Ideal for Prototyping Small and Complex Parts

Early stages of design often involve lots of changes. A laser cutting service helps you move from one version to the next quickly. If a hole needs to shift by 2mm or a new slot needs to be added, that can be done in minutes — not days.

For one-off parts, short runs, or small batches, laser cutting is an affordable option. And thanks to its high accuracy, there’s no guesswork involved. You get exactly what you designed.

How a cnc cutting machine Supports Clean and Accurate Designs

Laser cutting is great for detail work, but many shops also use a cnc cutting machine to handle thicker or tougher materials. CNC stands for Computer Numerical Control, and it follows precise digital instructions to cut materials.

When paired with laser cutting, a cnc cutting machine gives engineers more options. Here’s when it’s especially useful:

-

Cutting metal plates that are too thick for a laser

-

Producing high volumes of the same shape

-

Creating bevelled or deep edge cuts

The best part is that these machines talk to each other. You can cut the design with a laser cutting service, and then send it straight to the cnc cutting machine for finishing or extra detail. It’s all part of making sure your part is perfect.

The Role of Turret Punching Services in Sheet Fabrication

Punching vs Cutting: What’s the Difference?

While lasers cut by melting or burning through material, turret punching works like a cookie cutter. It uses mechanical force to punch shapes into metal sheets.

Turret punching services are ideal when you need:

-

Lots of holes in the same shape

-

Repeating slots or corners

-

Cost-effective production for large batches

It’s not as precise as a laser, but for the right job, it’s quicker and more economical.

Great for High-Volume or Repeating Patterns

Let’s say you need 500 identical metal brackets. You could use a laser, but turret punching services might be faster and cheaper. It’s designed for speed and repeatability — two things engineers love when working on production-ready designs. Many manufacturers will combine turret punching with a laser cutting service depending on the material and project size.

Add Shape with Sheet Metal Bending Press Options

After cutting out flat parts, the next step in many engineering projects is bending them into shape. That’s where a sheet metal bending press comes in. Laser cutting gives you the outline, but the sheet metal bending press gives your part structure. It folds the material with exact angles, so it fits perfectly into a frame, machine, or panel.

This method works well with materials like:

-

Mild steel

-

Aluminium

-

Stainless steel

-

Galvanised sheets

If you’re building something with moving parts or enclosures, bending is usually needed. The cleaner the bend, the better the fit — and the less chance you’ll need to rework it later.

It’s worth noting that bending requires skill. If done wrong, it can stretch or crack the material. That’s why it’s best to work with a team that understands both cutting and forming.

Combining Laser Cutting Service with Sheet Metal Press Brake Tools

Why Pairing Services Speeds Up Production

A good laser cutting service doesn’t just stop at cutting. Many now offer complete sheet metal fabrication in-house. That means you can get your part cut, bent, and ready to go — all under one roof.

Adding a sheet metal press brake to the process lets fabricators shape the piece exactly to your design specs. It’s an essential part of the workflow for things like:

-

Brackets

-

Enclosures

-

Frames

-

Structural parts

By combining these services, you reduce:

-

Handling time

-

Errors from shipping between providers

-

Overall project delays

Cut, Form, Finish – All in One Shop

When looking for a provider, ask if they offer:

-

Laser cutting service

-

Turret punching services

-

CNC cutting machine operations

-

Sheet metal press brake work

-

Sheet metal bending press options

Getting everything done in one place can save time and money. It also means your team has one contact point for any questions, changes, or revisions. Whether you’re a mechanical engineer, product designer, or small business, having all these services under one roof gives you peace of mind.

Final Thoughts

Prototyping doesn’t need to be expensive or complicated. With access to modern tools like a laser cutting service, cnc cutting machine, and sheet metal bending press, you can go from idea to finished part faster than ever before.

Here’s a simple reminder of why this approach works:

-

Laser cutting service: Gives fast, clean cuts

-

Turret punching services: Best for repeat patterns and big batches

-

Cnc cutting machine: Handles heavy-duty jobs or tricky cuts

-

Sheet metal bending press: Shapes your part into something useful

-

Sheet metal press brake: Provides strong, clean folds with precision

Engineers and fabricators across Australia are using this combined approach to create everything from prototypes to final products. So whether you’re designing a bracket, a casing, or a custom part — you’ve got the tools to get it done right.