A cnc cutting machine brings accuracy and repeatability to metalwork. Designs move from CAD to the shop floor with minimal manual handling. This reduces errors and keeps quality consistent across every batch. CNC control also speeds up production. Programs can be saved, tweaked, and rerun for future jobs. That means less setup time and faster turnarounds. It suits many sectors.

Think construction hardware, architectural metalwork, signage, transport, and engineering parts. With a cnc cutting machine, teams waste less material too. Tight nesting and precise paths make better use of each sheet. That is good for the budget and the environment.

Comparing cnc cutting machine and laser cutting service

When a cnc cutting machine is the right choice

Choose a cnc cutting machine when you need flexible processes across many materials and thicknesses. It handles complex tool paths, bevels, and multi-step operations. It is ideal when you want tight tolerances and repeatable runs day after day.

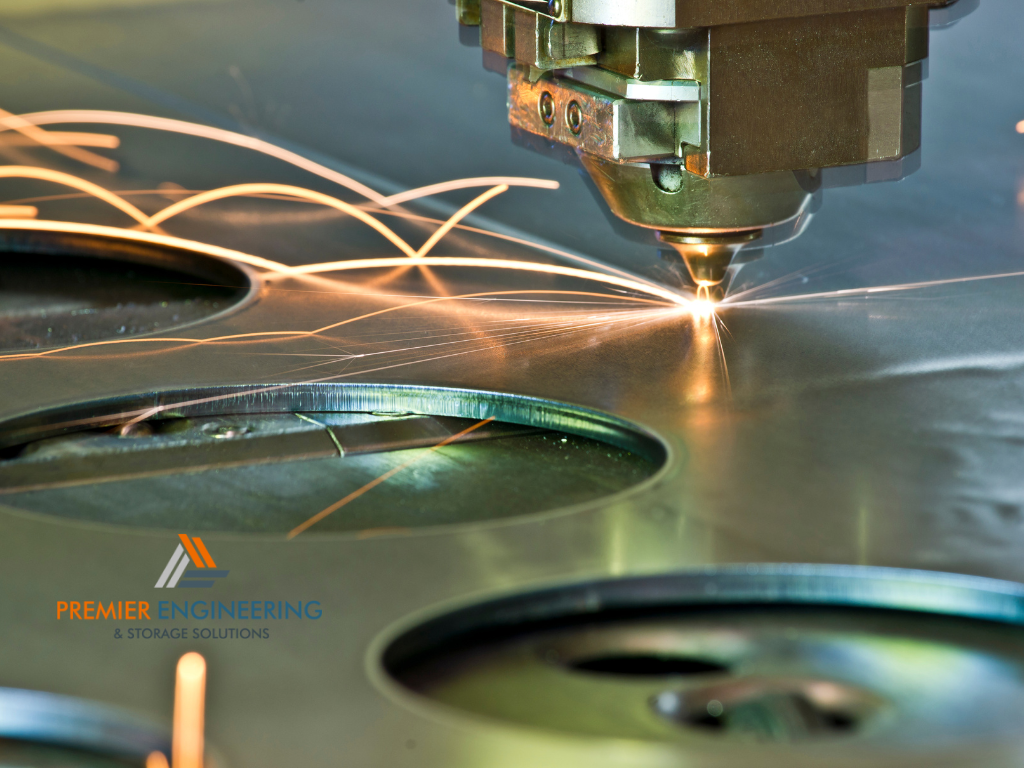

How a laser cutting service delivers speed and accuracy

A laser cutting service shines on thin to medium sheet with fine detail. laser cutting produces clean edges that need little finishing. It is fast on profiles with many curves or small holes. Outsourcing to a specialist also reduces your in-house maintenance and staffing needs.

Key differences in cost and finish

-

Setup costs are lower when you outsource one-off or short runs

-

In-house CNC pays off on repeat work and steady volumes

-

laser cutting often gives a smoother edge on thin sheet

-

Mechanical CNC methods can suit thicker plate or parts that need forming later

The best choice depends on volume, material, and the finish required.

How laser cutting shapes industrial projects

laser cutting is popular because it balances speed and precision. The beam follows complex paths without changing tools. That keeps cycle times short and results consistent. It works well on mild steel, stainless, and aluminium. It also handles intricate logos, vents, and decorative patterns.

For many workshops, laser is one step in a bigger workflow. Cut parts can move straight to folding, tapping, or welding. The clean edges save sanding time. That helps teams hit deadlines without sacrificing quality.

If jobs vary a lot, partnering with a trusted laser cutting service gives you capacity on demand. You scale up for peaks, then pull back when things quieten down.

Using an industrial steel cutting machine for heavy projects

Handling thicker steel with precision

Some work calls for more muscle. An industrial steel cutting machine manages heavy plate and structural sections with stable, accurate cuts. It keeps tolerances tight even on thicker material, which makes downstream assembly easier.

Safety and durability in tough conditions

Heavy-duty frames, guarded drives, and robust tables help operators stay safe. Machines built for rough environments keep alignment true, shift after shift. That reliability reduces rework and scrap.

Saving time on large-scale jobs

On large projects, speed matters. Automated feeds, smart fixturing, and efficient tool paths cut lead times. Teams can run longer nests overnight and come back to finished parts in the morning. That frees people to focus on welding, forming, and final assembly.

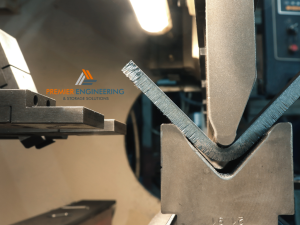

Where turret punching services fit in metal fabrication

turret punching services are essential when you need repetitive patterns like holes, slots, or special cut-outs in sheet metal. A turret press can hold a range of tools, making it quick to switch between shapes. This makes it perfect for producing panels, enclosures, and ventilation parts.

One of the key benefits is speed. Unlike slower manual methods, turret punching services handle high volumes with consistent quality. They also reduce the need for secondary drilling or milling, cutting down on labour and overall cost.

For workshops, turret punching services often work best alongside a cnc cutting machine or a laser cutting service, filling in gaps where speed and efficiency matter most.

Boosting efficiency with combined methods

How workshops mix CNC, laser, and turret punching

Many fabrication businesses now use multiple machines together. A cnc cutting machine may handle the main profiles, while laser cutting finishes off fine detail, and turret punching services add functional holes or designs. This blended approach helps achieve the best results in less time.

Achieving faster turnaround times

By combining methods, projects move quickly through each stage. CNC does the heavy work, laser delivers precision cuts, and turret punching adds the finishing touches. This teamwork reduces downtime and helps meet tight deadlines.

Reducing waste while keeping costs down

Smart use of machines also lowers scrap levels. CNC nesting, clean laser cuts, and efficient punching mean more parts per sheet. Less waste means more profit and a smaller impact on the environment.

Final thoughts on choosing the right cutting method

Every job has its own needs. A simple bracket might only need a cnc cutting machine, while decorative panels may call for a laser cutting service. For heavy-duty parts, an industrial steel cutting machine is often the best option.

The key is balance. Think about cost, accuracy, volume, and finish. By matching the right machine to the right job, workshops save time and boost quality. Adding turret punching services where needed makes production even smoother.

- In the end, using a mix of CNC, laser cutting, and other tools is not just about efficiency. It’s about giving customers the best product possible, on time and within budget.