When you start looking at a laser cutting service, one of the first questions is usually about price. The truth is, there is no single answer because costs can shift depending on the project. The good news is that laser cutting is valued because of its efficiency and accuracy, which often makes it a cost-effective choice in the long run.

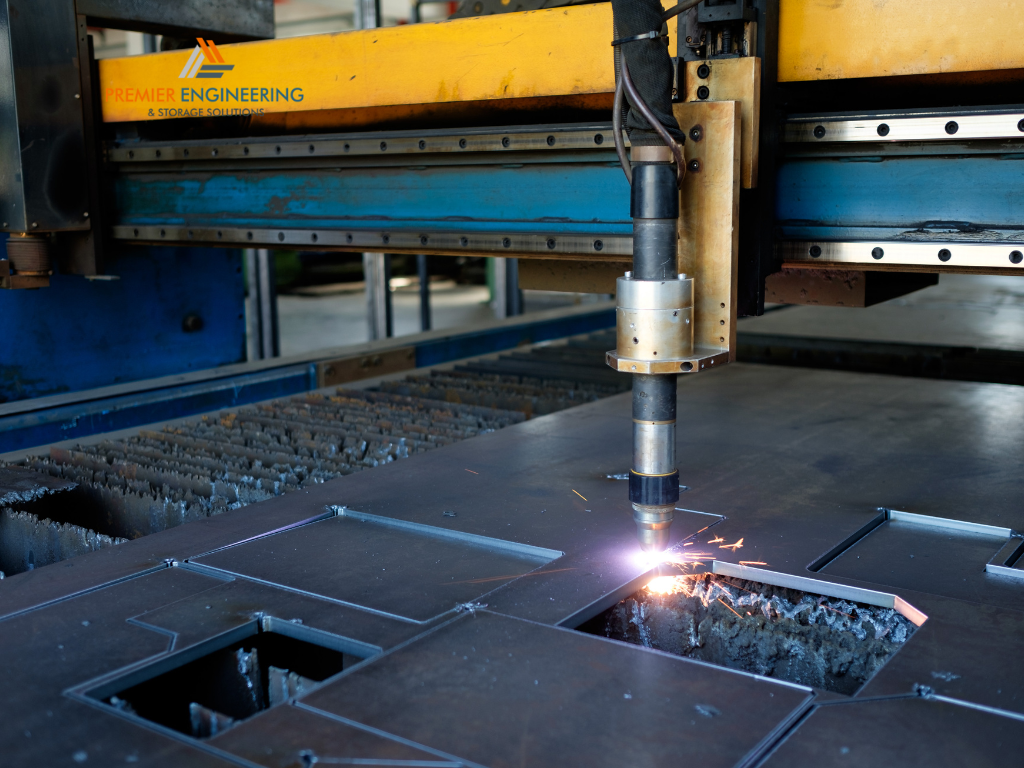

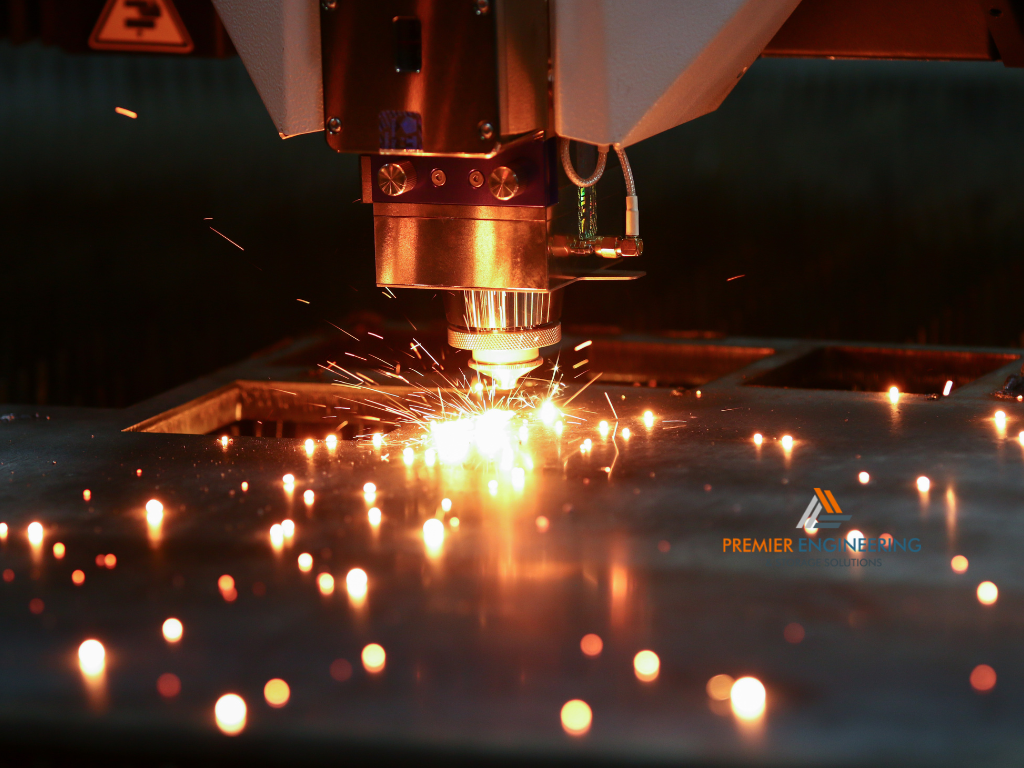

A laser cutting service works by using focused beams to cut through materials with precision. It is fast, versatile, and works with a wide range of materials, from thin plastics to thick metals. The ability to achieve sharp edges and detailed designs makes it ideal for industries like construction, automotive, and signage.

While it may sound high-tech, the principle is simple. The laser does the hard work, but the pricing depends on several factors, including the material, design complexity, and the type of machine used. This is why understanding what affects the cost helps you plan better and avoid surprises.

How a cnc cutting service Adds Value to Projects

Accuracy across repeated jobs

A cnc cutting service is a big part of modern manufacturing. CNC means computer numerical control, which simply means that machines are guided by digital programs. When combined with laser technology, it allows for accuracy that humans cannot achieve on their own. Every cut is repeatable and consistent, even if you are producing thousands of identical parts. This level of precision reduces waste, saving both time and money.

Flexible designs for different materials

Another way a cnc cutting service adds value is through flexibility. With programming, you can switch easily between materials like steel, aluminium, or acrylic. This makes it useful for industries that need different outputs without a complicated setup process.

Here are some key benefits of using CNC alongside laser cutting:

-

Less risk of error compared to manual work

-

Faster turnaround for bulk orders

-

Consistent quality across all pieces

By reducing mistakes and speeding up production, CNC makes the whole process more efficient. While this technology may raise upfront costs, it often lowers the overall project price by cutting down on material waste and labour.

The Impact of a cnc cutting machine on Pricing

The type of cnc cutting machine used also plays a major role in the price of a laser cutting service. Not all machines are the same. Some are designed for lighter jobs, while others handle thick steel or very detailed patterns. Advanced machines are faster, more precise, and capable of working with complex designs, but they also cost more to operate. Energy use is another factor. High-powered lasers consume more electricity, and this can be reflected in the overall cost of the job.

Maintenance and setup times also matter. If a cnc cutting machine needs to be recalibrated for every new material, the preparation adds to the price. Still, the right equipment ensures quality results. Customers often find that paying slightly more for advanced machines saves them in the long term because the cuts are accurate, the turnaround is quicker, and there is less need for secondary finishing work.

Exploring engineering manufacturing and fabrication capabilities

Scale of production jobs

When looking at the cost of a laser cutting service, the scale of the job matters a lot. Small one-off pieces may cost more per unit because of setup time, while large production runs are often more economical. This is tied to the overall engineering manufacturing and fabrication capabilities of the provider. A workshop with advanced machines, automated systems, and skilled staff can handle bigger jobs at a better price per part.

Skills and workforce involved

Labour also plays a role. While much of the work is automated, experienced operators are needed to set up the machines, monitor the process, and make adjustments if needed. The higher the skill level required, the more it can affect pricing. That said, skilled teams ensure higher quality results and fewer mistakes, which saves money in the long run.

In short, strong engineering manufacturing and fabrication capabilities give customers confidence. They show that the provider can handle complex projects on time, without sacrificing precision.

Material Costs in laser cutting Projects

The type of material being cut is another major cost factor. Each material reacts differently to the laser, and some need more time, power, or preparation.

For example:

-

Thin aluminium or acrylic is quicker to cut, which keeps costs lower.

-

Thicker steel sheets take longer and use more energy, which increases the price.

-

Specialty metals like stainless steel may require higher-grade machines or additional finishing.

Waste material can also influence costs. Efficient use of sheets, with designs arranged closely together, reduces leftover scraps and saves money. Some providers pass these savings on to customers.

In many cases, customers can bring their own material, but suppliers often source high-quality stock that suits the machine and ensures cleaner cuts. Discussing materials upfront is one of the best ways to manage project costs effectively.

The Role of an industrial steel cutting machine in Costing

Handling heavy-duty materials

For projects that involve very thick or tough metals, an industrial steel cutting machine comes into play. These machines are designed for heavy-duty work and can cut through materials that standard lasers cannot handle. The use of such equipment often increases costs, but it is necessary for certain applications like construction beams, automotive parts, or specialised components.

Balancing speed with precision

While an industrial steel cutting machine may have higher operating costs, it also brings advantages. It can cut larger sheets in less time, and it delivers the kind of precision needed for safety-critical industries. This balance of speed and quality helps explain why jobs that require this level of machinery are priced differently from lighter cutting tasks.

At the end of the day, customers pay not only for the cut itself but also for the capability of the equipment. Investing in the right machine ensures that projects are completed safely, on schedule, and with the accuracy required for long-term performance.