In today’s fast-paced industrial world, precision and speed are everything. That’s where CNC (Computer Numerical Control) comes in. When paired with an industrial steel cutting machine, CNC takes manual guesswork out of the equation. Every cut is guided by a programmed path, resulting in clean, consistent results—no matter how many pieces you’re producing.

This level of control boosts accuracy down to fractions of a millimetre and drastically reduces material waste. No more second-guessing cuts or relying on operator skill alone—CNC ensures repeatability from the first piece to the thousandth. For businesses focused on volume, precision, and time-efficiency, CNC is not just helpful—it’s a must.

Why it’s now essential in engineering manufacturing and fabrication capabilities

Whether you’re in heavy fabrication, structural steelwork, or precision part manufacturing, CNC has become the backbone of modern engineering manufacturing and fabrication capabilities. The demand for tight tolerances, custom designs, and rapid delivery times has pushed traditional cutting methods to the side.

By combining intelligent automation with industrial-grade power, CNC-enabled machines help shops meet client expectations without slowing down production. More importantly, they give engineers and designers more freedom to innovate—because now, almost anything they can draw can be cut cleanly and accurately.

How CNC Supports Complex Designs with Ease

From simple parts to intricate shapes—CNC makes it possible

One of the biggest advantages of using cnc cutting services is flexibility. Whether you’re cutting basic rectangles or artistic curves with internal cutouts, CNC can handle it with ease. You simply upload your CAD drawing, and the machine does the rest—flawlessly translating that design into steel, time after time.

This is especially valuable for industries that work with custom parts, signage, enclosures, or brackets. What once took hours of manual effort—or wasn’t possible at all—can now be done in minutes, with extreme consistency. Even intricate ventilation panels, gear components, or decorative steelwork become manageable with CNC on your side.

Supporting advanced engineering manufacturing and fabrication capabilities

In modern fabrication, it’s not enough to be fast—you have to be adaptable too. That’s where CNC truly shines. It gives workshops the ability to take on more complex, high-value jobs without adding more manual labor or sacrificing accuracy.

With engineering manufacturing and fabrication capabilities constantly evolving, CNC-controlled equipment ensures you’re ready for whatever project comes next. Whether you’re producing a prototype or managing a large run of custom parts, CNC gives you the edge to stay competitive, reliable, and precise.

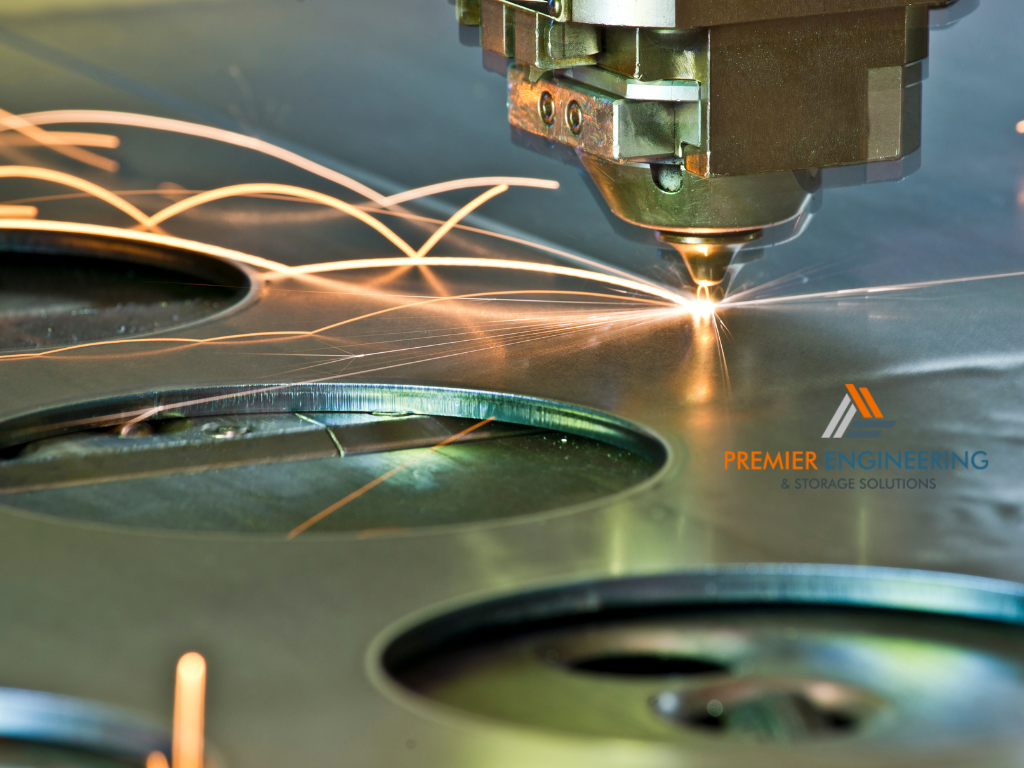

Laser Cutting with CNC: Fast, Clean, and Consistent

Why CNC-controlled laser cutting offers superior edge quality

Laser cutting has long been known for its precision and speed—but add CNC control to the mix, and it becomes a game-changer. With CNC guidance, the laser head follows a precise path determined by your design file. The result? Incredibly clean edges, smooth contours, and minimal distortion even on the thinnest or most delicate materials.

This level of detail is especially important in industries like signage, automotive, or architectural steelwork, where appearance and fit really matter. CNC-controlled laser cutting not only enhances quality, it saves time by reducing the need for post-cut finishing like sanding or grinding.

When to choose a laser cutting service for your steel projects

If your project requires high accuracy, clean edges, and complex patterns, a laser cutting service is the clear choice. CNC-powered laser cutting is ideal for steel signage, perforated panels, detailed branding elements, machine parts, and more.

And when you partner with specialists offering both laser cutting service and cnc cutting services, you get the full benefit of expert advice, faster lead times, and results that elevate your project. It’s not just about cutting steel—it’s about doing it better, faster, and smarter.

Integrating CNC with Other Cutting Technologies

Using cnc cutting services for plasma, waterjet, and laser systems

While laser cutting often gets the spotlight, CNC isn’t limited to just one technology. In fact, many workshops integrate cnc cutting services across multiple cutting systems—like plasma, waterjet, and router machines. Each method has its strength, and CNC makes it easier to switch between them while maintaining consistent precision.

For example, waterjet cutting is perfect for heat-sensitive metals, while plasma offers faster cuts for thick steel. CNC enhances all of these by giving the operator tight control over the cut path, speed, and accuracy. Whether you’re doing a rough fabrication job or something extremely detailed, CNC brings precision to every cutting method.

The advantage of hybrid workflows with a single control system

A big benefit of CNC integration is workflow efficiency. With one control system across different machines, your team can move from design to finished part without delays or miscommunication. It also simplifies training, improves consistency, and speeds up production across the board.

Shops offering cnc cutting services can manage both high-volume and custom jobs without changing their entire setup. That flexibility saves time and keeps you competitive in a fast-moving market.

CNC Efficiency That Reduces Waste and Saves Time

How smart programming improves material use and productivity

With steel prices rising and turnaround times tightening, smart resource use is more important than ever. CNC helps solve this with nesting software and precision programming that maximizes every sheet of material. Instead of guesswork, you get tightly laid out cut paths with minimal offcuts.

In a busy shop using an industrial steel cutting machine, this kind of efficiency translates into real savings—less scrap, fewer errors, and more output per hour. Your team spends less time reworking mistakes and more time getting jobs out the door.

Benefits of automation in day-to-day steel cutting operations

CNC also boosts productivity by automating much of the cutting process. Once programmed, your machine can run with minimal supervision—cutting parts consistently, shift after shift. This means smaller teams can manage larger workloads without sacrificing quality.

For businesses focused on engineering manufacturing and fabrication capabilities, this level of automation is a huge win. It supports better planning, faster delivery, and more predictable costs—all of which lead to happier clients and stronger margins.

Choosing the Right CNC System for Your Industrial Steel Cutting Machine

What to consider when upgrading or investing in CNC controls

If you’re running an older industrial steel cutting machine, upgrading to a CNC control system can completely transform your workflow. But not all systems are created equal. When choosing a CNC solution, think about the types of jobs you do most, the materials you cut, and how complex your designs are.

Key factors to compare include software compatibility, cutting speed, ease of programming, and support from the supplier. Some CNC setups offer more flexibility or better integration with design software—which can save you time with every project.

Working with experts in laser cutting service and cnc cutting services

Choosing the right CNC system often comes down to working with the right people. Companies that specialise in laser cutting service and cnc cutting services—like those with real experience in steel cutting—can help guide your investment based on what actually works in the field.

They’ll help you avoid overspending on features you don’t need, while ensuring you get a system that delivers reliable, precise results. Whether you’re scaling up or modernising your operations, the right CNC system is more than just an upgrade—it’s a foundation for long-term success.