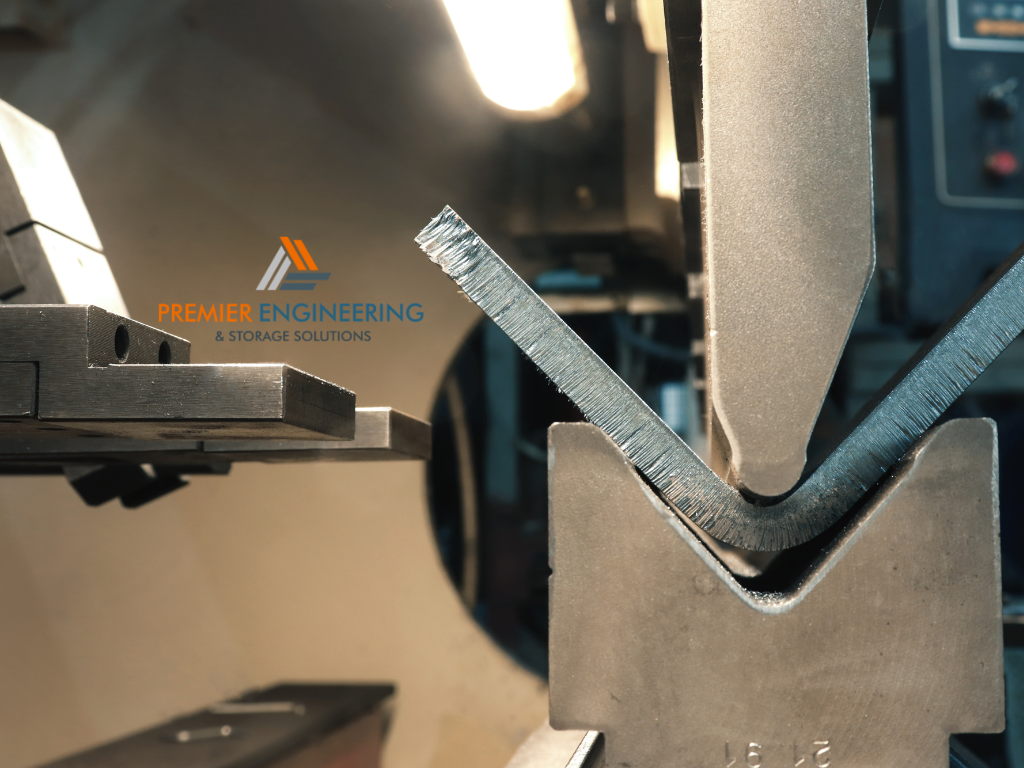

In custom fabrication, accuracy isn’t just a bonus — it’s essential. When working with metal, even small mistakes can cause major issues. Parts might not fit. Holes may be off-centre. And the overall structure could end up weak or unbalanced. That’s why a sheet metal bending press is so useful. It gives you precise control over every bend. Whether you’re shaping panels, brackets or architectural pieces, the press ensures clean lines and accurate angles every time.

For businesses that create custom products — like balustrades, kitchen panels or signage — this kind of consistency saves both time and money. The last thing you want is to remake a job because the bend was a few degrees off. Using a metal bending press also helps maintain quality across multiple pieces. If you’re fabricating five or fifty units, each one will match the last, which is exactly what your clients want.

Flexibility and Speed with a Metal Bending Press

Small Runs? No Problem

Not every project involves bulk orders. In fact, many custom jobs involve small batches or one-off designs. That’s where the metal bending press really shines. Because the machine is so adaptable, you won’t waste time switching tools or resetting measurements. That means faster turnaround times and more flexibility in your workshop.

It can quickly be set up for new jobs and adjusted for different metals and thicknesses. This makes it perfect for:

-

Custom signage

-

Hospitality fit-outs

-

Shopfitting parts

-

Electrical enclosures

-

Architectural features

You can also bend a variety of materials — from aluminium to cnc stainless steel — depending on the job. This gives your clients more choice and lets you offer a broader range of services without extra equipment.

Better Quality Cuts with CNC and Laser Support

Precision starts with a clean cut. That’s why many workshops pair their sheet metal bending press with cnc cutting services or laser cutting equipment. These tools create accurate shapes that are ready for bending, with minimal finishing needed. When you cut and bend in the same workflow, you save time and reduce waste. There’s no need to fix jagged edges or adjust misaligned holes. The combination of cnc cutting services and bending means smoother operations and better results for your clients.

Laser technology is also great for detailed work. It’s ideal for decorative pieces or complex patterns that standard tools can’t manage. A proper laser cutting service will provide sharp edges and tight tolerances, which means your bent metal looks better and fits perfectly.

Why CNC Stainless Steel Bending Saves Time and Money

Consistency Without the Headaches

When you’re working with cnc stainless steel, accuracy is the name of the game. CNC systems (computer numerical control) let machines do the thinking for you, following programmed measurements to the millimetre.

Pairing CNC tech with a sheet metal bending press or metal bending press allows your workshop to deliver:

-

Uniform bends every time

-

Reduced labour hours

-

Minimal material waste

That means lower costs, fewer errors, and happy customers.

Because stainless steel is tough, getting clean bends without warping or cracking requires both strength and smarts. The CNC setup tells the press exactly where and how to apply force, which helps avoid common issues like springback or surface damage.

Whether you’re fabricating outdoor panels, kitchen splashbacks, or custom hardware, cnc stainless steel bending helps maintain high quality without slowing you down.

What to Expect from a Professional Laser Cutting Service

A reliable laser cutting service can make a big difference in your fabrication project. Laser machines use heat and precision beams to slice through sheet metal with clean, sharp results.

This matters because:

-

Clean cuts = better bends

-

Precise measurements = parts that fit

-

Less post-processing = faster delivery

Working with a team that offers both laser cutting and cnc cutting services means you can get everything done in one place. That saves time, cuts costs, and reduces the risk of errors between stages. If you’re outsourcing, look for a provider with a good reputation and modern equipment. They should be able to handle a variety of materials and job sizes while maintaining fast turnaround times.

Final Thoughts: Getting the Most from Your Fabrication Project

Investing in a sheet metal bending press is a smart move for any custom metal workshop. It improves quality, saves time, and gives you more control over every job — whether you’re doing small-batch work or large builds. But don’t stop at bending. Combining a metal bending press with services like laser cutting and cnc cutting services opens the door to faster workflows and better results.

If you’re working with cnc stainless steel, or need fine detail and edge quality, make sure your team or supplier has the tools and know-how to deliver. And if you ever need professional help, a reliable laser cutting service can bring precision and polish to your project. Custom fabrication is all about balance — between speed, quality and cost. And with the right tools and support, you can hit all three.