Homeowners, interior designers, and businesses across Australia are now choosing laser cutting for custom furniture and décor. It’s easy to see why. Whether you’re refreshing a home office, fitting out a café, or creating a standout sign, a good laser cutting service brings accuracy, style, and speed together.

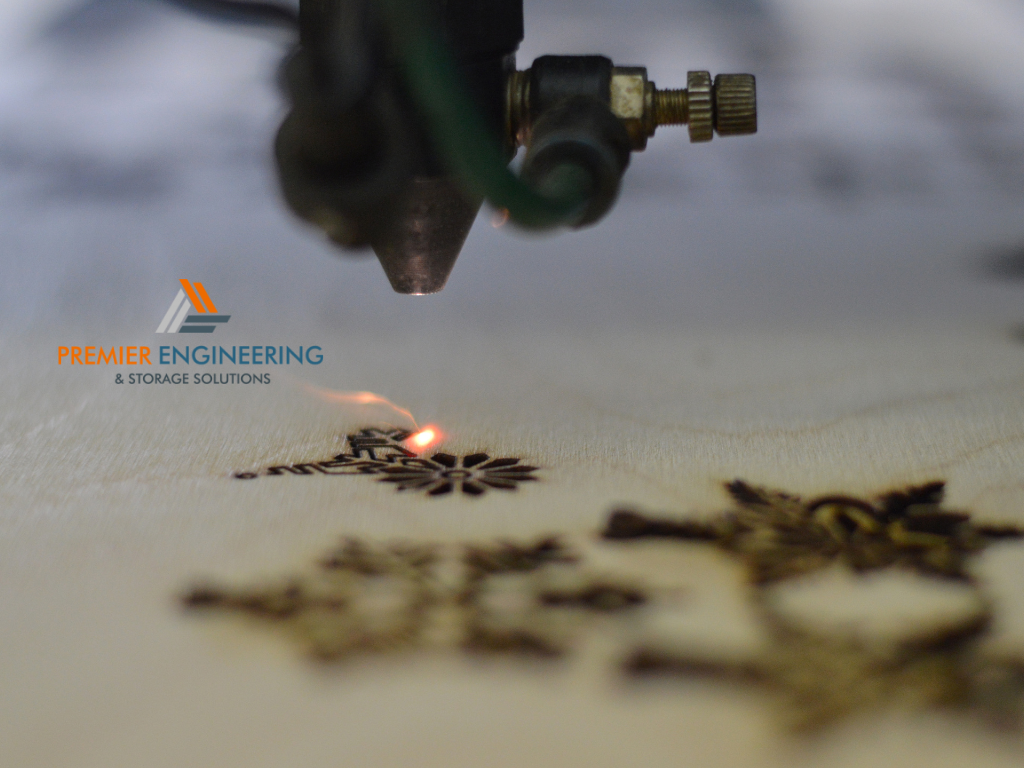

Unlike traditional methods, laser cutting is much more precise. That means smoother edges, no splintering, and much less waste. You can use it on everything from wood and acrylic to steel and aluminium. The results are clean, consistent, and ready to impress.

Designers love that they’re not limited by what’s on the shelf. With laser cutting, you can make truly unique pieces that suit your style, not just what’s trending.

The Role of a Laser Cutting Service in Furniture Design

Precision, style, and flexibility in one process

A modern laser cutting service helps turn creative ideas into real, functional furniture pieces. Whether you’re making a single custom chair or designing hundreds of matching wall panels, the process is reliable and repeatable.

What makes it so effective?

-

Clean precision – Cuts are accurate down to the millimetre

-

Design flexibility – Works well for curves, patterns, and detailed logos

-

Material versatility – Handles wood, plastic, glass, and even metal

This means it’s ideal for everything from café signs and decorative shelving to minimalist light fixtures and bold wall dividers. Small-scale businesses also benefit. You don’t need to run thousands of items. You can just create one or two bespoke designs at a time.

How Laser Cutting Enhances Modern Furniture Styles

Contemporary furniture trends often focus on clean lines, clever shapes, and practical beauty. Laser cutting helps make these ideas real without breaking the bank or delaying production.

Whether you want a minimalist lamp stand or a feature wall with layered patterns, a laser cutting service delivers reliable results. The clean cuts suit timber veneers, clear acrylics, or brushed metal, depending on the vibe you’re after.

Plus, there’s a growing market for combining different materials. That’s where laser cutting shines. Wood and metal, acrylic and glass – all come together seamlessly with the right technique.

Furniture Parts That Benefit Most from Laser Cutting

Detailed work made easier

Some parts of furniture just need more attention. These are often time-consuming or too tricky to do by hand. Laser cutting changes that. Here are a few examples where it really makes a difference:

-

Table legs and frames – With symmetrical designs and tight joints

-

Chair backs – For curved edges or cut-out detailing

-

Wall panels – To add layered depth or branded shapes

-

Custom signage – For businesses or décor

-

Decorative trims – That give furniture a unique finish

When you combine this process with other tools like a cnc cutting machine or sheet metal bending press, you get even more creative freedom.

Combining Tools: How the Right Setup Boosts Quality

What supports a laser cutting service behind the scenes

To achieve the best results in laser cutting, having the right supporting tools is just as important as the laser cutter itself. These tools help shape, bend, and finish materials with accuracy and care.

Two standout additions include:

-

cnc cutting machine – Offers reliable, programmable cutting for thick or tough materials

-

sheet metal bending press – Used to form shapes or folds in metal sheets for frames or supports

Together, they give you more design freedom and help bring complex pieces to life, whether you’re working on custom shelving, retail counters, or signage frames.

Benefits of Using CNC Cutting Services

If you’re after a polished finish, cnc cutting services go hand-in-hand with laser cutting service options. CNC (computer numerical control) ensures materials are shaped with computer-guided precision, making it ideal for more demanding jobs.

Here’s why it’s worth considering:

-

Better consistency for bulk orders

-

Ideal for repetitive components

-

Supports materials not suitable for lasers (like very thick steel)

So, if you’re making both decorative and functional parts in one project, mixing both services gives you the best of both worlds.

Using an Industrial Steel Cutting Machine for Large Jobs

When power and durability matter most

For large-scale furniture, shelving systems, or structural parts, a industrial steel cutting machine is often needed. These machines are built to handle heavy-duty work, like thick steel plates or commercial-grade frames.

They are especially helpful when:

-

Making warehouse storage racks

-

Producing café and bar furniture with metal legs

-

Building shop displays needing strength and longevity

If you’re a business needing both design and performance, working with a company that offers this equipment helps you tick both boxes.

Choosing the Right Laser Cutting Service for Furniture Projects

Tips to help you get it right the first time

Before you jump in, here’s what to look for when selecting a laser cutting service:

-

Experience – Have they worked with furniture or interior projects before?

-

Material range – Can they handle wood, acrylic, and metal?

-

Finishing options – Do they offer bending, polishing, or painting?

-

Design support – Can they help improve your file or idea?

-

Customer service – Are they easy to contact and happy to help?

Also, don’t forget to ask if they offer both laser cutting and cnc cutting services, so you can mix and match where needed.

Final Thought: A Better Way to Build Custom Furniture

Today’s designers and makers don’t need to compromise. With the help of smart tools like a laser cutting service, a sheet metal bending press, and a cnc cutting machine, you can bring your vision to life easily, affordably, and quickly.

From unique wall art to strong furniture frames, these tools offer precision and possibility—without the stress. Whether you’re a DIY maker or a growing brand, tapping into the power of laser cutting can turn a good idea into a beautiful final product.