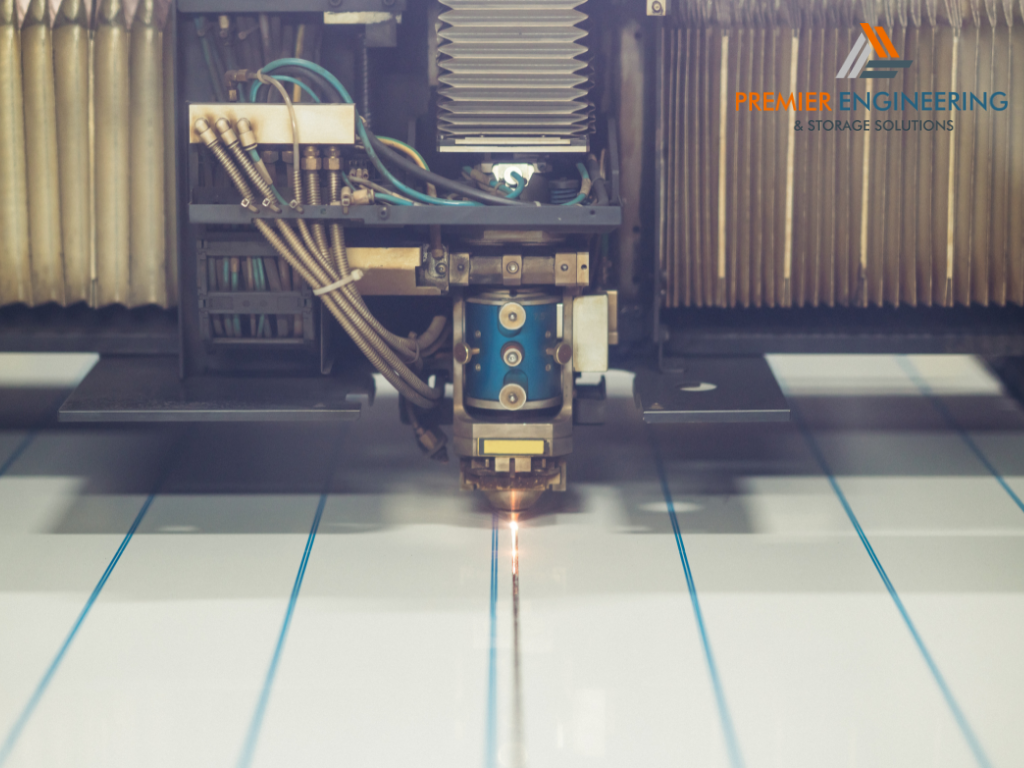

Custom laser cutting services in Sydney offer specialized solutions to businesses seeking precision and customization in their manufacturing processes. Laser cutting, a technique that uses a high-powered laser to cut and shape materials, is renowned for its accuracy, speed, and versatility. Custom services in Sydney cater to a diverse range of industries, from manufacturing and construction to design and art. These services provide businesses with the ability to tailor their projects to exact specifications, whether it’s intricate designs for artistic installations or precise components for industrial machinery.

Advantages of Custom Laser Cutting for Local Businesses

Custom laser cutting offers several significant benefits for Sydney businesses:

- Precision and Accuracy: Laser cutting allows for extremely precise cuts, essential for complex designs and tight tolerances.

- Versatility in Materials: A wide range of materials can be laser cut, from metals and plastics to wood and glass, offering flexibility in application.

- Efficiency and Speed: Laser cutting is a fast process, reducing production time and enabling quick turnarounds for projects.

- Cost-Effectiveness: Despite the high level of precision, laser cutting can be cost-effective, especially for high-volume or repeat orders.

- Customization: Perhaps the most significant advantage, it allows for limitless customization, enabling businesses to bring unique designs and ideas to life.

Identifying Business Needs for Custom Laser Cutting

Assessing Unique Business Requirements

To effectively leverage custom laser cutting, Sydney businesses first need to assess their specific requirements. This assessment involves understanding the project’s scope, the materials needed, the desired precision level, and the final application of the cut pieces. Businesses should also consider the volume of production – whether the project is a one-off prototype or a large-scale production run – as this can influence the choice of laser cutting service.

Matching Business Needs with Laser Cutting Capabilities

Different laser cutting technologies offer various capabilities, and it’s important to match these with business needs. For example, CO2 lasers are excellent for cutting, engraving, and etching on non-metal materials, whereas fiber lasers are more suited for working with metals. Understanding the strengths and limitations of each laser type ensures that the chosen technology aligns with the project’s specific requirements, resulting in the best possible outcome.

Design Aspects in Custom Laser Cutting

Designing for Laser Cutting

Designing for laser cutting requires a thoughtful approach. Key considerations include:

- Material Constraints: Each material has its unique properties, such as thickness and heat resistance, which must be considered in the design.

- Complexity of Design: While laser cutting allows for intricate designs, the complexity can impact the cutting time and cost.

- File Preparation: Designs need to be converted into a suitable digital format, typically vector files, which guide the laser cutter.

Collaborating with Designers and Specialists

Working with skilled designers and laser cutting specialists is crucial for achieving optimal results. These professionals can provide valuable insights into the laser cutting process, material selection, and design optimizations. They can also help troubleshoot potential issues and ensure that the final design is both feasible and cost-effective.

Material Selection for Custom Projects

Choosing the Right Materials

Selecting the right materials is a critical step in custom laser cutting projects. The choice depends on the project’s purpose, desired aesthetics, and functional requirements. Common materials used in laser cutting include various metals like steel and aluminum, plastics like acrylic and polycarbonate, wood, and even fabrics. Each material has its own set of properties that make it suitable for different applications. For instance, metals are ideal for durable, high-strength components, while acrylics are chosen for their aesthetic appeal and versatility.

Material Properties and Laser Cutting Compatibility

Understanding how different materials interact with laser cutting processes is essential. Factors such as melting point, thickness, and reflectivity can significantly impact the cutting process. Materials with a high melting point or reflectivity, like certain metals, require more powerful lasers. Similarly, the thickness of the material determines the laser power needed for a clean cut. It’s also important to consider any potential material deformations caused by the heat generated during the laser cutting process.

Technological Advancements in Laser Cutting

Leveraging Advanced Laser Cutting Technology

Sydney’s laser cutting industry has access to state-of-the-art laser cutting technologies, offering enhanced precision, speed, and flexibility. Modern laser cutters are equipped with features like faster cutting speeds, greater accuracy, and the ability to cut complex shapes with minimal waste. These advancements not only improve efficiency but also expand the creative possibilities for custom projects.

Innovations Beneficial to Sydney Businesses

Technological advancements in laser cutting that are particularly beneficial for Sydney businesses include automation features and software integration. These innovations allow for more precise control over the cutting process, resulting in higher-quality outputs. Additionally, developments in laser power and efficiency enable handling a broader range of materials, thus widening the scope of potential projects.

Cost Considerations and Budgeting

Estimating Costs for Custom Laser Cutting Projects

Budgeting effectively for a custom laser cutting project involves several considerations. The cost is influenced by factors such as the type and thickness of the material, the complexity of the design, and the total cutting time. For an accurate estimate, it’s recommended to consult with laser cutting providers who can assess the specifics of your project and provide detailed quotations.

Balancing Quality and Cost in Custom Solutions

Achieving the best value without compromising quality is a key goal in custom laser cutting projects. To balance quality and cost:

- Opt for materials that offer the best trade-off between cost and performance for your specific application.

- Simplify designs where possible to reduce cutting time and complexity, thereby lowering costs.

- Consider the economies of scale, as larger production runs often reduce the cost per unit.

Execution and Implementation

From Design to Reality: Executing Custom Projects

The process of executing custom laser cutting projects involves transforming conceptual designs into tangible products. This journey starts with finalizing the design, often created using specialized software that translates the design into a format compatible with laser cutting machines. Once the design is set, the chosen material is prepared and loaded into the laser cutter. The cutting process is then carefully monitored to ensure precision. After the cutting phase, the pieces may undergo additional processes such as cleaning, polishing, or assembly, depending on the project requirements. This step-by-step approach ensures that the initial vision is accurately brought to life.

Quality Assurance and Testing

Quality assurance and testing are integral parts of the execution process. After the laser cutting is complete, each piece is inspected for accuracy, dimensions, and any potential defects. This might include measuring the cut components, checking the smoothness of edges, and ensuring the overall quality meets the specified standards. For projects that require assembly, it is also crucial to test how the components fit and function together. This rigorous quality control guarantees that the final product not only aligns with the design specifications but also upholds the high standards expected in professional laser cutting.

Conclusion

Looking towards the future, the field of custom laser cutting in Sydney is poised for further growth and innovation. Technological advancements are expected to continue, bringing even greater precision and new capabilities to laser cutters. Trends such as automation and the integration of artificial intelligence may further streamline the process, enhancing productivity and creativity. As businesses in Sydney increasingly recognize the potential of custom laser cutting, its role in various sectors is likely to expand, cementing its place as a key technology in modern manufacturing and design.