Speed matters in product development. The faster you can go from concept to a working prototype, the sooner you can test, improve, and launch. That’s where cnc cutting services make a big difference. Unlike traditional methods that rely on manual measuring and cutting, CNC technology works directly from your digital design.

It removes the guesswork, saves hours of labour, and delivers exact results—every time. Whether you’re testing a small part or producing a fully functional prototype, CNC cutting makes it faster and easier to get it right the first time.

Instant adjustments using CAD files with cnc cutting services

With cnc cutting services, adjustments are easy. You can edit your CAD file and upload a new version, and the system is ready to cut again with no retooling. That flexibility is perfect for early-stage development when changes happen often.

If you’re building, testing, or refining a design, CNC gives you a repeatable process with no manual setup or delays. It keeps your ideas moving forward without needing to stop and start from scratch.

When to Use Laser Cutting for Faster Turnaround

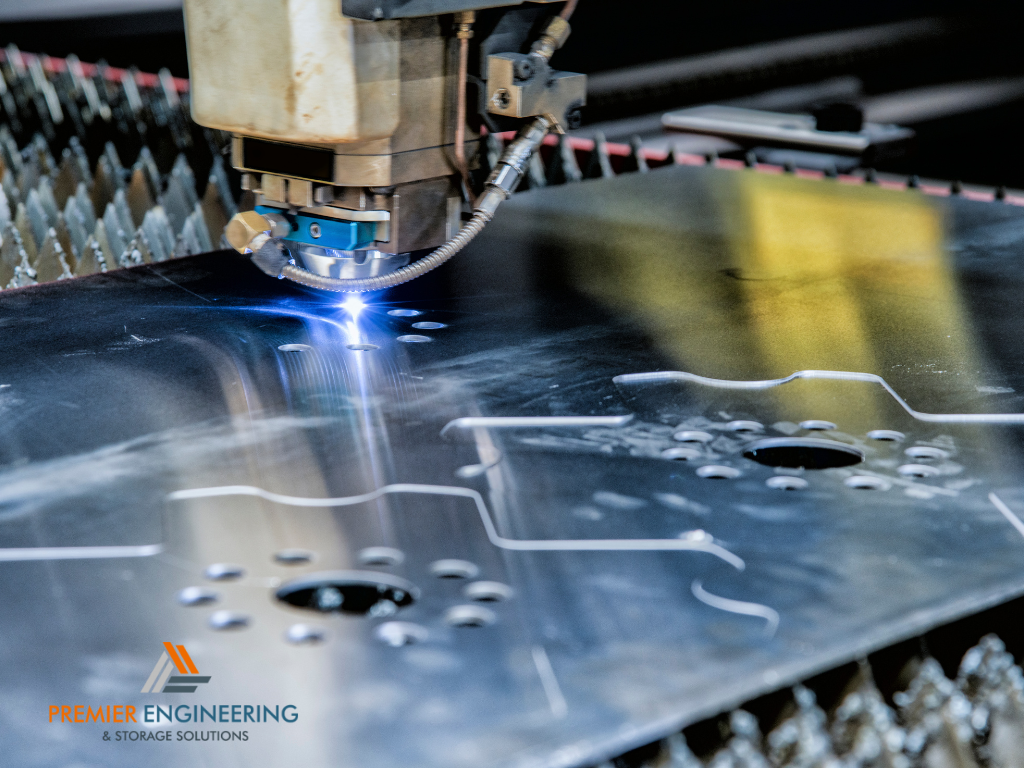

The speed and accuracy of modern laser cutting systems

When timelines are tight, laser cutting offers a fast and clean solution. It’s one of the most precise methods available, especially for thinner materials like acrylic, MDF, or sheet metal. Modern machines can cut complex shapes with incredible detail—without slowing down production.

Because there’s no physical contact with the material, there’s less wear on tools, fewer mechanical errors, and smoother results. That means fewer post-cut adjustments and quicker assembly.

Ideal use cases for a high-precision laser cutting service

A laser cutting service is ideal for signs, architectural panels, product enclosures, packaging inserts, or any job that requires detailed cuts with clean edges. It’s also perfect for industries like fashion, electronics, interior design, and tech prototyping where fine detail and speed matter.

For one-off samples or high-volume parts, laser cutting is efficient, repeatable, and cost-effective—especially when paired with CNC for large projects.

CNC Sheet Metal Fabrication for Strong, Scalable Components

How cnc sheet metal fabrication supports custom and batch production

Need to go from a prototype to short-run production? CNC sheet metal fabrication makes that possible. It allows you to scale up quickly without changing your process. You can use the same CAD design that worked for your prototype to produce 10, 100, or even 1,000 units—without sacrificing quality.

The precision of cnc sheet metal fabrication means parts fit together perfectly and are ready for welding, bending, or assembly. It’s a smart way to bridge the gap between development and manufacturing without needing a full production line.

Common materials, finishes, and structural benefits

CNC sheet metal fabrication works with a wide range of materials like aluminium, stainless steel, copper, and galvanized steel. It also supports different finishes—like powder coating, brushing, or polishing—based on your end use.

This process gives you both strength and design flexibility. Whether you’re building structural frames, enclosures, brackets, or custom panels, CNC-fabricated metal parts offer lasting durability and high visual appeal.

Turret Punching Services and the Benefits of High-Speed Hole Cutting

What turret punching services add to your prototyping capabilities

When your design requires lots of holes, slots, or patterns in sheet metal, turret punching services are the way to go. This method uses pre-set tool shapes to quickly punch through material with incredible speed and precision.

For prototype parts like brackets, vents, or control panels, turret punching is faster than laser or CNC cutting—especially when you’re making repetitive holes or standard features. It helps speed up early testing by creating accurate, ready-to-use parts in less time.

When punching is more efficient than cutting

Turret punching services are ideal when you’re working with uniform shapes and consistent cut patterns. It’s not only fast but also cost-effective, especially for medium- to large-sized production runs.

If you’re comparing cutting vs punching, consider the material type, thickness, and number of repeats. While laser cutting is better for intricate or varied designs, turret punching shines when your cuts are consistent and layout-driven.

How Integrated Cutting Services Help Teams Work Faster

Seamless file sharing and cloud-based revisions

Speed isn’t just about how fast machines cut—it’s also about how smoothly your team can work together. With digital cnc cutting services, designers, engineers, and manufacturers can all work from the same file in real time. That means no re-drawing, no remeasuring, and no communication gaps.

Whether your team is in one office or spread across different locations, CNC files can be reviewed, revised, and approved in minutes. This helps keep momentum going and reduces costly mistakes or delays.

Coordinating between design, cutting, and assembly

When your cutting provider offers CNC, laser cutting, and turret punching services under one roof, it saves a huge amount of time. Instead of sending files to multiple vendors, you can handle everything through a single production partner.

This streamlines your process—from file creation and material prep to cutting and finishing—and allows you to move from design to assembly with less back and forth. At scale, this integration means faster delivery and smoother communication across every stage.

Short-Run Manufacturing with CNC for Fast Market Entry

Why startups and small brands choose cnc cutting services

If you’re launching a new product or testing a limited edition, you don’t need full-scale manufacturing right away. That’s why many startups and niche brands turn to cnc cutting services for short-run production.

You can manufacture small batches with professional quality—without investing in tooling or large MOQs (minimum order quantities). Whether it’s 5 units or 500, CNC provides the same precision and repeatability you’d expect from a full factory.

Cost-effective solutions for limited-edition or trial product runs

Small production runs are perfect for market testing, customer feedback, or launching a pilot version of your product. And because cnc sheet metal fabrication and laser cutting work from digital files, you can tweak designs between runs with little cost or downtime.

This flexibility helps you stay agile, respond to customer feedback quickly, and launch confidently—without overcommitting on inventory or budget.