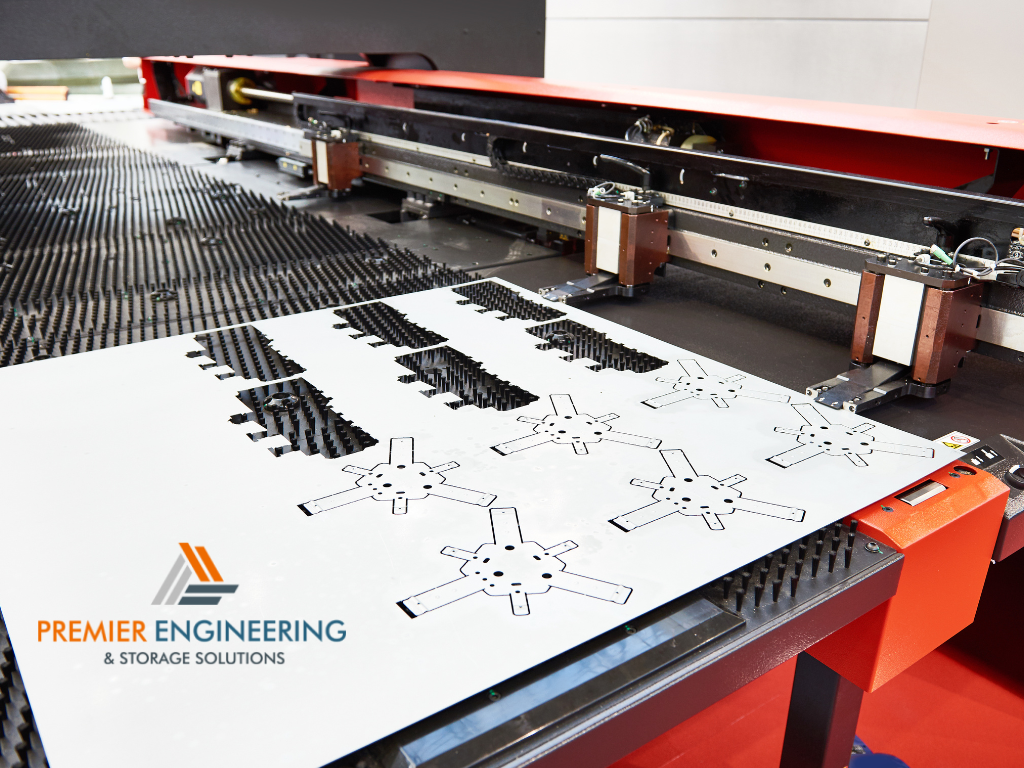

Turret punching services are celebrated for their exceptional precision and reliability. These machines use advanced tools and a rotating turret system to punch shapes, holes, and patterns into metal sheets with pinpoint accuracy.

The process is guided by computer programming, ensuring each punch is performed exactly where it’s needed. This makes turret punching perfect for projects requiring intricate details and consistent results across large production runs.

Can it handle small and intricate shapes?

Yes, turret punching services excel at creating small and intricate shapes. The flexibility of the turret press allows for detailed patterns, tight tolerances, and complex designs. With a variety of tools available, it can produce everything from simple holes to custom shapes with ease.

This capability makes turret punching ideal for applications like metal storage cabinets and industrial shelving units, where precise features are essential for functionality and aesthetics.

How Does Turret Punching Compare to CNC Cutting Services?

What are the key differences?

Both turret punching services and CNC cutting services are valuable for metal fabrication, but they differ in their approach and applications.

- Turret Punching: Best for repetitive tasks like creating perforations, slots, and standard shapes quickly and efficiently.

- CNC Cutting: Utilises cutting-edge technology, such as lasers or plasma, for detailed and intricate cuts, especially in thicker or non-flat materials.

Turret punching is often faster for high-volume projects, while CNC cutting is preferred for more complex or decorative designs.

When should you choose turret punching over CNC cutting?

Choose turret punching services when you need:

- High-speed production for large batches.

- Repetitive shapes like those found in industrial shelving units.

- Cost-effective fabrication for thinner metal sheets.

For projects requiring fine-edge finishes or non-standard contours, laser cutting or CNC cutting services might be a better fit.

Can Turret Punching Create Custom Features for Metal Storage Cabinets?

What customisation options are available?

Turret punching services are perfect for customising metal storage cabinets. They can add:

- Ventilation holes: Ensuring airflow for stored items.

- Slots and mounting holes: Allowing for easy assembly or attachment of accessories.

- Unique patterns: Adding aesthetic appeal while maintaining functionality.

These features are achieved with high precision, ensuring the cabinets are both functional and visually appealing.

Why is precision important for storage solutions?

Precision is critical for storage solutions like metal storage cabinets because every component must fit perfectly. Poorly aligned holes or patterns can affect the structural integrity and usability of the cabinets.

Turret punching ensures consistent accuracy, allowing cabinets to meet exact specifications. This makes them reliable for heavy-duty use in industries like manufacturing, logistics, and warehousing.

How Are Industrial Shelving Units Enhanced by Turret Punching?

What features can turret punching add?

Industrial shelving units benefit greatly from the precision and versatility of turret punching services. Key features include:

- Perforations for airflow: Prevents moisture build-up and enhances storage safety.

- Custom slots and labels: Makes shelving units adaptable and easy to organise.

- Reinforced holes for bolting: Adds strength and stability to support heavy loads.

These features improve the functionality and durability of shelving units, making them a preferred choice for industrial use.

Why choose turret punching for shelving projects?

Turret punching is ideal for shelving projects because of its ability to handle high volumes while maintaining accuracy. Durable materials, like steel and aluminium, can be processed without compromising quality.

Moreover, the process is cost-effective, ensuring industrial shelving units are manufactured efficiently without sacrificing the customisation options needed for various applications.

What Tools and Technology Support Precise Turret Punching Services?

How do modern machines ensure accuracy?

Modern turret punching machines are equipped with advanced technology to ensure exceptional accuracy. These machines use computer-controlled systems, often referred to as CNC (Computer Numerical Control), to guide the punching process.

This precision eliminates human error, ensuring each punch is placed exactly where it should be. Additionally, the use of advanced tooling allows the machine to switch between different shapes and sizes quickly, making it versatile for various projects.

What role does technology play in consistency?

Automation plays a significant role in maintaining uniformity, especially in large-scale projects. Once the program is set, the machine can repeat the punching process hundreds or thousands of times without deviation.

This level of consistency is essential for projects like metal storage cabinets and industrial shelving units, where every piece must align perfectly for assembly. Modern tools and technology ensure reliable results, even for complex or bulk orders.

Can Turret Punching Be Combined with Laser Cutting?

How do these methods complement each other?

Turret punching services and laser cutting are complementary techniques that, when combined, can produce outstanding results. Turret punching excels at creating repetitive features like perforations, slots, and mounting holes.

Laser cutting, on the other hand, is perfect for intricate edges and non-standard shapes. Together, they allow for designs that are both functional and aesthetically pleasing, providing the best of both worlds.

What are the benefits of combining both techniques?

Combining turret punching with laser cutting offers several advantages:

- High-quality results: Achieve sharp edges and precise patterns.

- Multifunctional products: Produce items like decorative panels, shelving units, or enclosures that require a mix of functional and aesthetic features.

- Cost efficiency: Use turret punching for repetitive tasks and laser cutting for detailed work to optimise time and resources.

This approach ensures that every part of the project is completed to the highest standard.

What Factors Impact the Precision of Turret Punching Services?

How do material thickness and type affect results?

Material properties play a significant role in the precision of turret punching. Thicker materials like steel may require more force, which can slightly affect the sharpness of the punch. Conversely, thinner materials like aluminium are easier to process but may deform if not handled correctly.

The type of material also matters. For example:

- Stainless steel: Requires robust tooling due to its hardness.

- Aluminium: Lightweight and easier to punch, but more prone to scratches.

Understanding these factors ensures the right approach for each project.

Why does tooling quality matter?

High-quality tools are essential for achieving clean and precise cuts. Worn or low-grade tooling can result in jagged edges, inaccurate shapes, or damage to the material.

For applications like industrial shelving units, where durability and precision are critical, using top-tier tools ensures a professional finish and long-lasting performance.

How Can Turret Punching Meet the Demands of Custom Projects?

What industries benefit from custom turret punching?

Turret punching services are versatile and widely used across various industries, including:

- Storage solutions: Custom designs for metal storage cabinets and shelving.

- Construction: Components for structural frameworks and decorative panels.

- Manufacturing: Parts for machinery, enclosures, and electronic housings.

These industries rely on turret punching for its ability to create tailored solutions quickly and efficiently.

How does turret punching handle high-demand projects?

Turret punching is ideal for high-demand projects because of its speed and efficiency. Machines can process large quantities of material in a short time while maintaining accuracy.

For example, mass-producing industrial shelving units or perforated panels is seamless with turret punching. Its reliability ensures consistent results, even when dealing with bulk orders, making it an invaluable tool for meeting custom project needs.