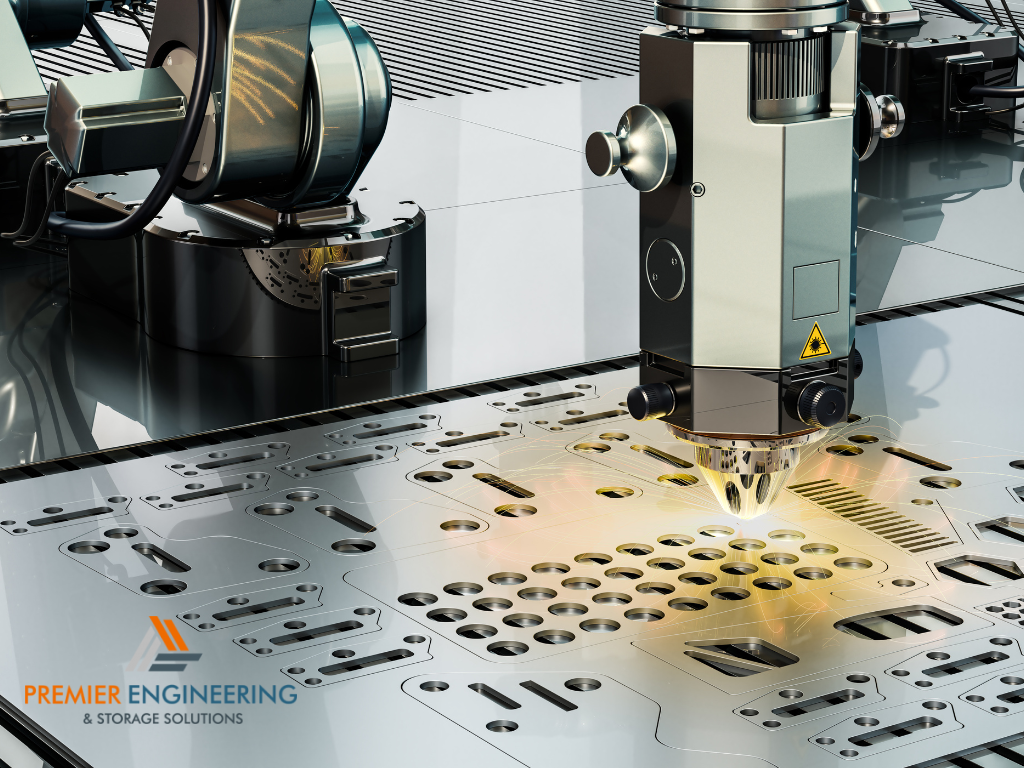

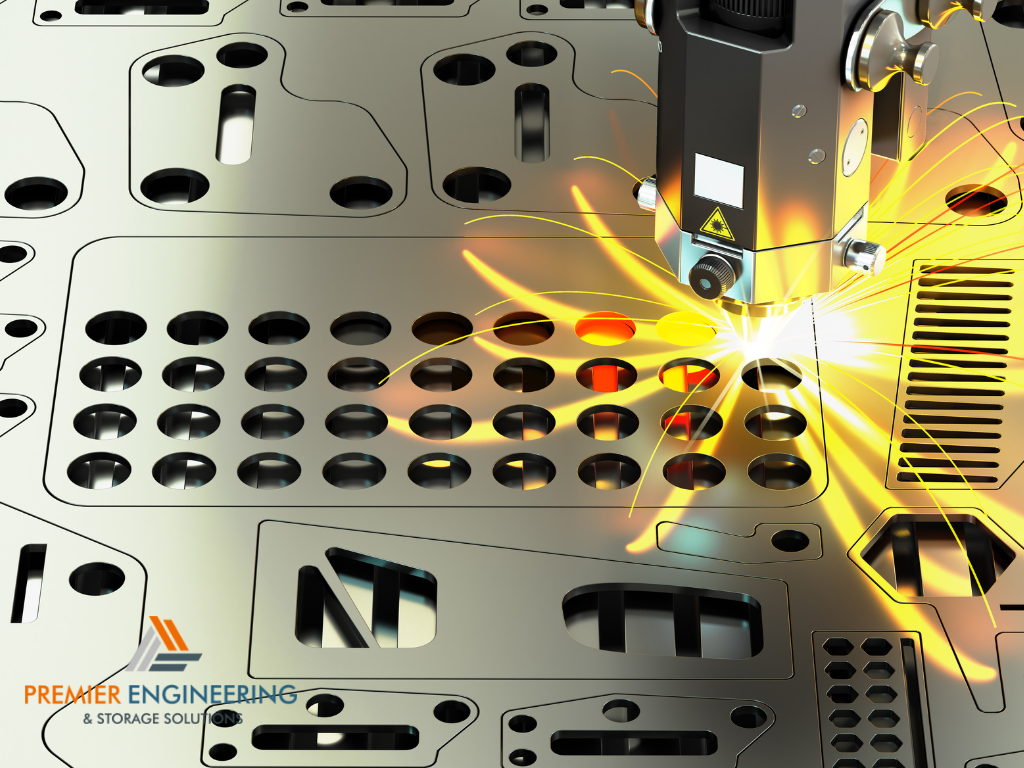

Steel laser cutting is a precise and versatile technology widely used in the fabrication of metal, including artistic and decorative projects. This technique employs a high-powered laser beam to cut precise designs into various types of steel, allowing for intricate patterns and fine details.

What is Steel Laser Cutting, and How is It Used in Artistic and Decorative Creations?

Steel laser cutting services involves directing a concentrated laser beam to cut steel materials into specific shapes and designs. In artistic and decorative applications, this process enables the creation of complex geometric patterns, delicate cutouts, and intricate motifs that are difficult to achieve with traditional metalworking techniques. Artists and designers utilize laser cutting to produce sculptures, decorative panels, architectural details, and bespoke furniture, among other artworks.

Why is Laser Cutting Preferred for Artistic Steel Metal Fabrications?

Laser cutting is preferred in artistic steel metal fabrications for several reasons:

- Precision and Detail: The laser beam can achieve extremely fine cuts, which is ideal for detailed artistic designs.

- Efficiency and Speed: Laser cutting is much faster than manual cutting methods, allowing for quicker production of complex pieces.

- Versatility: It can be used on various thicknesses and types of steel, and programmers can easily adjust patterns and designs.

- Clean Cuts: The method produces clean and sealed edges that reduce the need for additional finishing, enhancing the overall aesthetic of the piece.

Designing Art with Steel Laser Cutting

The design phase is crucial in transforming an artistic concept into a tangible metal artwork using laser cutting technology.

How do Artists and Designers Conceptualize Works that Incorporate Steel Laser Cutting?

Artists and designers begin by sketching out their ideas, which often involve thematic elements, geometric patterns, or naturalistic imagery. These initial concepts are then refined through discussions with metal fabricators to ensure the designs are feasible for laser cutting. The collaborative process may involve several iterations to balance artistic vision with the technical limitations of steel fabrication.

What Software or Tools are Essential for Designing Intricate Patterns and Details in Metal Art?

To prepare designs for laser cutting, artists use various CAD (Computer-Aided Design) software tools such as AutoCAD, Adobe Illustrator, or CorelDRAW. These programs allow designers to create precise digital models of their artwork, which can be directly translated into instructions for the laser cutting machinery. This software not only helps in detailing the aesthetics but also ensures the designs are optimized for the cutting process, including adjusting kerf (the width of the material removed by the laser beam) and nesting patterns to minimize waste.

Techniques and Processes in Steel Laser Cutting for Art

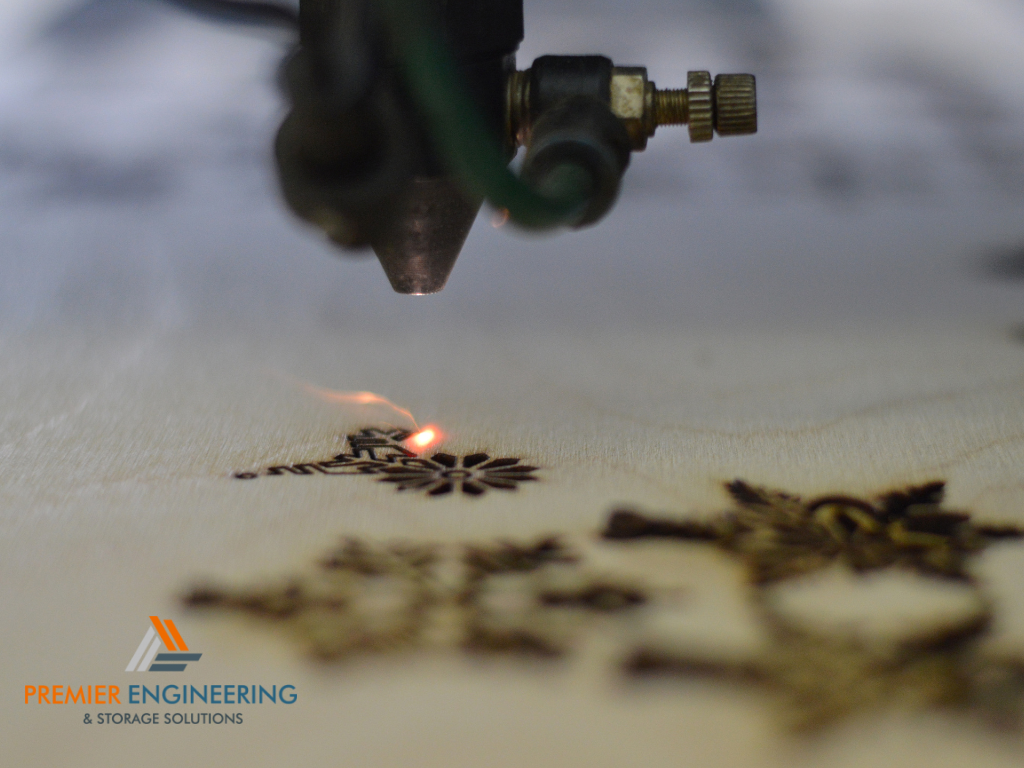

Various specialized techniques in laser cutting cater specifically to artistic applications, enhancing both the visual appeal and structural integrity of the artworks.

What Specific Laser Cutting Techniques are Used to Create Artistic Details in Steel?

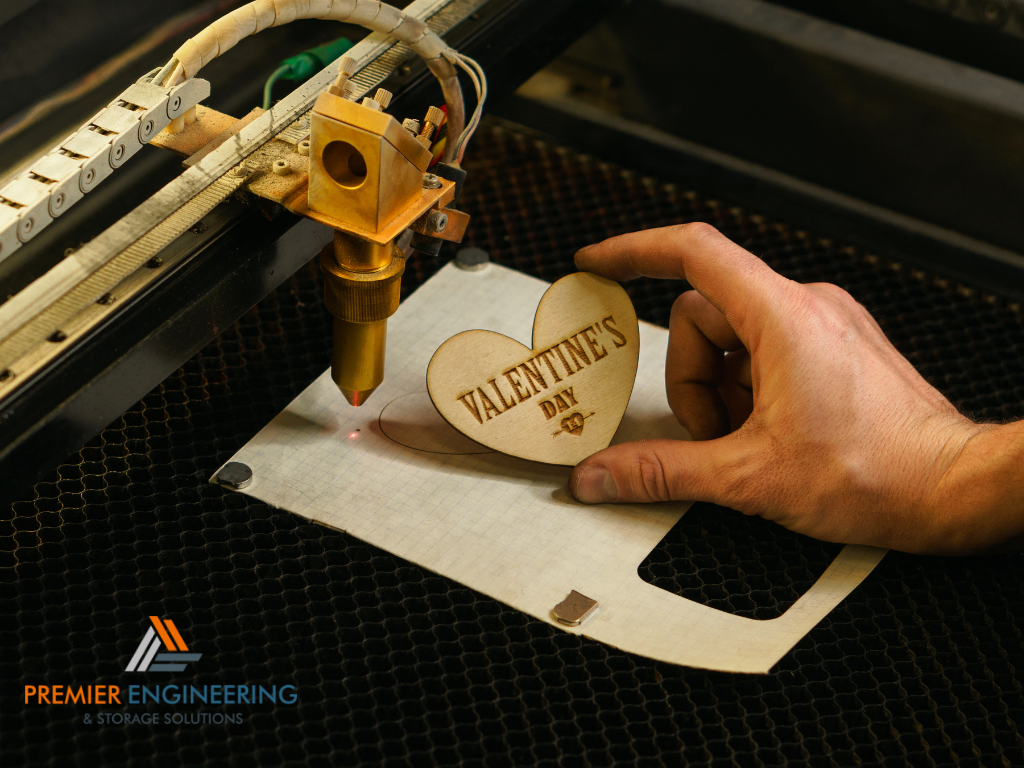

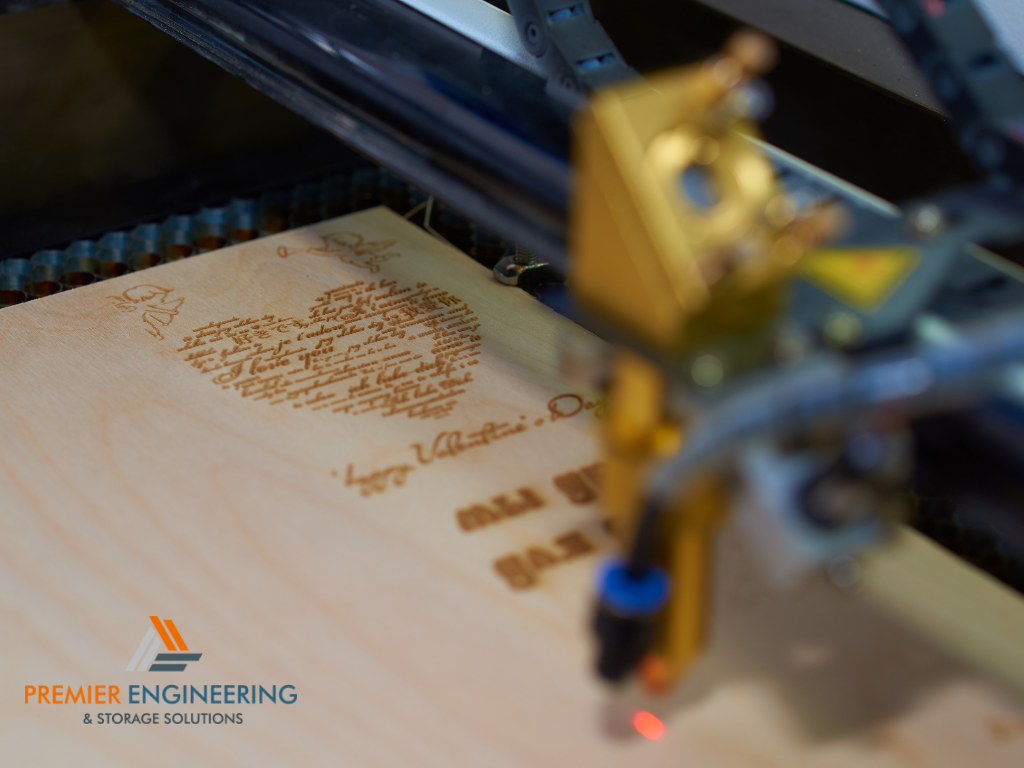

Artistic steel laser cutting services often involves layering, etching, and engraving techniques to add depth and texture to flat sheets. Advanced laser cutters can adjust power settings to vary the depth of the cut, creating three-dimensional visual effects and intricate textures that add complexity to simple steel sheets.

How Do These Techniques Enhance the Aesthetic and Structural Elements of the Artwork?

Laser cutting allows for precise control over every aspect of the cutting process, which means that even the most delicate designs can be executed without damaging the material. The ability to produce consistent, repeatable cuts ensures that even in large-scale or multi-part installations, every component fits perfectly with the next. Aesthetically, the precision of laser cutting provides a crisp, clean look that is visually striking, while structurally, the integrity of the material is maintained, ensuring durability and longevity of the artwork.

Materials and Finishes in Steel Art

Choosing the right type of steel and finishing processes is crucial for the success of any artistic project involving laser cutting.

What Types of Steel are Best Suited for Artistic Laser Cutting?

- Mild Steel: Popular for its excellent laser cutting properties and affordability. It’s ideal for indoor artworks or those with protective finishes to prevent rust.

- Stainless Steel: Highly valued for its rust resistance and smooth finish, making it perfect for both indoor and outdoor art installations.

- Corten Steel: Known for its weathered appearance and natural rusting capabilities, which provide protective layer without compromising structural strength, ideal for outdoor sculptures.

What Finishing Processes are Available to Enhance and Protect Laser-Cut Steel Artworks?

- Powder Coating: Provides a durable and visually appealing finish in a wide range of colors, protecting the steel from corrosion and wear.

- Galvanizing: Especially used for outdoor steel artworks to protect against rust and degradation.

- Patination: Chemical process used primarily with corten and other steels to accelerate the formation of a stable rust layer that provides a distinctive appearance and protective barrier.

Examples of Steel Laser-Cut Art and Decor

Laser-cut steel is versatile, lending itself to a variety of artistic and decorative applications.

What are Some Common Decorative Items Made Through Steel Laser Cutting?

- Wall Art: Intricate designs that can be hung as focal points in homes or galleries.

- Garden Sculptures: Durable artworks that complement outdoor spaces with their intricate patterns and robust structure.

- Architectural Elements: Includes decorative panels, balustrades, and façade elements that enhance the aesthetic of buildings and interiors.

How Has Laser-Cut Steel Been Integrated into Public Art and Commercial Decor?

- Public Installations: Large-scale sculptures and installations in parks and public spaces that often become landmarks.

- Commercial Spaces: Custom signage, decorative screens, and detailed framework in hotels, offices, and retail environments that elevate the commercial property’s visual appeal.

Collaboration Between Artists and Fabricators

The partnership between artists and metal fabricators is essential for bringing complex artistic visions to life.

How Do Artists Collaborate with Steel Metal Fabricators to Realize Their Creative Visions?

Artists typically start with a concept or design, which they discuss with fabricators to explore feasibility and techniques. The fabricator’s role is to provide technical advice, suggest suitable materials and finishes, and ultimately translate the artistic designs into physical artworks using their tools and expertise.

What are the Benefits of This Collaboration for Both Artists and Fabricators?

- For Artists: Gaining access to professional expertise, advanced equipment, and materials that might otherwise be out of reach, allowing for more ambitious and intricate designs.

- For Fabricators: Opportunities to work on unique, creative projects that can showcase their skills and open up new markets and clients interested in artistic metalwork.

Challenges and Solutions in Artistic Steel Laser Cutting

Artistic ventures often encounter unique challenges, especially when merging traditional artistic methods with advanced technologies like laser cutting.

What Challenges Do Artists Face When Working with Steel Laser Cutting Services?

- Design Limitations: Converting artistic visions into laser-ready designs can be complex, especially for artists unfamiliar with digital design tools.

- Material Constraints: Different types of steel respond differently under a laser, which can affect the accuracy and detail of the cut.

- Cost Efficiency: The cost of laser cutting can be prohibitive for larger or more intricate projects, limiting the scope of what artists can realistically create.

How Are These Challenges Addressed to Ensure the Final Product Meets Artistic Standards?

- Collaborative Design Process: Working closely with laser cutting experts and utilizing their knowledge to adapt designs without compromising the artistic intent.

- Material Testing: Conducting trials on small samples to determine the best settings for the desired quality and detail.

- Cost Management: Leveraging advancements in laser cutting technology to reduce waste and improve cutting efficiency, thereby making larger projects more affordable.

The Future of Artistic Steel Laser Cutting

The field of artistic steel laser cutting is rapidly evolving, driven by continual advancements in technology.

What are Emerging Trends and Technologies in Steel Laser Cutting for Art?

- Increased Automation: Automated laser systems that can streamline production, reduce costs, and allow for more precise cuts.

- Enhanced Precision: Newer laser systems offer greater control over laser parameters, enabling finer details and cleaner cuts.

- Integration with 3D Technologies: Combining 3D printing with laser cutting to create mixed-media sculptures and complex structures.

How Might Advancements in Laser Cutting Technology Further Transform Artistic Metal Fabrication?

As laser cutting technology advances, artists will have greater creative freedom to explore complex and intricate designs that were previously unattainable. These technologies not only enhance the precision and flexibility of artistic expressions but also open up new avenues for innovation in metal art, making it more accessible to a broader audience.

Conclusion

The fusion of laser cutting technology and artistic metal fabrication illustrates a perfect blend of creativity and innovation. As this technology continues to evolve, it will undoubtedly usher in new artistic possibilities, further blurring the lines between traditional craftsmanship and digital fabrication. This evolution not only enriches the artistic community but also enhances the cultural landscape, making art more interactive, accessible, and integrated with the environments in which we live.

One response to “Steel Laser Cutting for Artistic and Decorative Purposes”

[…] Laser cutting is often integrated with other fabrication methods such as bending, welding, and assembly to streamline production processes. This integration allows for the creation of complex structures and components with high precision and minimal processing time. By combining laser cutting with bending, for example, manufacturers can produce parts that are ready for assembly almost immediately after cutting, reducing the need for secondary processing. […]