Both CNC punching services or turret punching can be used when cutting sheet metal fabrication material. With the development of both technologies, manufacturers can use both laser cutting methods. Many of the laser cutting providers mainly focus on the new capabilities and better ways of turret punches also have plenty of utilities. An experienced operator can perform any of the high-quality work in the proper way with any of these machines, whether CNC Laser cutting or Turret punching machine.

Difference between CNC Laser cutting and Turret Punching Machine

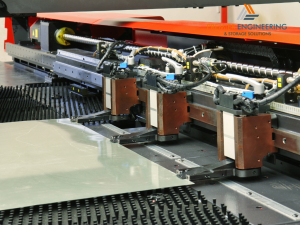

Turret Punching: During the turret punching process, the operator places a sheet of metal between a punch and a die. The punch presses into the material, pushing excess metal into the die. Computer numerical control (CNC) turret punching uses computer programming to follow a design’s direction. This coding allows the punch to perform an automated cutting process.

Laser cutting: Laser cutters use a focused beam and gas to vaporize sheet metal. The beam cuts through the metal, then a stream of gas blows through the cut area to form the desired cut-out. Coated mirrors guide and focus the laser beam while shielding it from the operator’s eyes. A laser cutter can also use CNC technology to automate the vaporization process.

Each machine suits different situations better than the other. A turret punch can fit more applications than some professionals may think.

VERSATILITY OF CNC TURRET PUNCHING VS. LASER CUTTING

A turret punch and laser cutting services can have similar levels of versatility, depending on the model used. Generally, laser cutters can cut into thicker material than turret punches. Advanced turret punch models have stronger cutting power that allows them to work with more metals. Turret punches can perform more secondary operations than laser cutters, including:

Tapping

Blanking

Forming

Extruding

Deburring

With a turret punch machine, a fabrication shop can save time and money on processes that laser cutters cannot handle. To get more information call us on 0481 115 752