Laser cutting technology has become a cornerstone in the automotive industry, revolutionizing how vehicles are designed and manufactured. This advanced fabrication method offers unparalleled precision, speed, and flexibility, allowing automotive manufacturers to push the boundaries of innovation and efficiency. The adoption of laser cutting in automotive processes signifies a shift towards more sophisticated production techniques that align with the industry’s growing demands for quality, customization, and sustainability.

Laser cutting’s significance in automotive manufacturing and design cannot be overstated. It enables the production of complex components with intricate details that would be difficult, if not impossible, to achieve with traditional cutting methods. Moreover, its ability to work with a wide range of materials supports the industry’s exploration of new designs and the integration of novel materials into vehicle construction, further contributing to advancements in safety, performance, and aesthetic appeal.

Laser Cutting Technologies in Automotive Manufacturing

Overview of Laser Cutting Processes

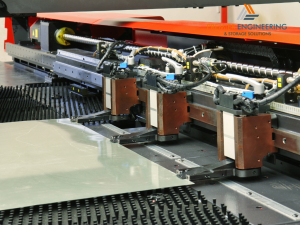

The automotive industry employs various laser cutting technologies, with CO2 and fiber lasers being the most prevalent. CO2 lasers, known for their versatility, are used extensively for cutting, engraving, and even welding a wide range of materials, including metals, plastics, and composites. Fiber lasers, on the other hand, offer advantages in cutting reflective materials like aluminum and copper alloys, which are increasingly used in automotive manufacturing due to their lightweight properties.

Advantages Over Traditional Cutting Methods

Compared to traditional mechanical cutting techniques, laser cutting stands out for its precision and efficiency. It eliminates the need for tooling changes and physical contact with the workpiece, reducing wear and the likelihood of material deformation. This non-contact process also minimizes material waste, making it a more sustainable option for automotive production. Furthermore, the high level of automation associated with laser cutting machines enables faster production cycles and supports the industry’s move towards just-in-time manufacturing practices.

Applications of Laser Cutting in Automotive Production

Body Components and Chassis

Laser cutting is instrumental in producing body components and chassis with high precision, contributing to vehicles’ lightweight and structural integrity. The technology’s accuracy ensures clean cuts and exact fits, essential for modern automotive designs that rely on complex geometries and tight tolerances to enhance aerodynamics and fuel efficiency.

Interior Components

In the realm of interior components, laser cutting is used to create parts with enhanced aesthetics and functionality. From intricate dashboard elements to custom trim pieces, laser cutting allows for the precise fabrication of components that meet the high-quality standards expected by consumers.

Prototyping

Rapid prototyping is another area where laser cutting technology shines in the automotive industry. It allows designers and engineers to quickly turn concepts into functional prototypes, accelerating the development process. This agility is crucial in today’s competitive market, where speed-to-market can be a significant advantage.

Innovations in Automotive Design Enabled by Laser Cutting

Customization

Laser cutting technology has opened new avenues for customization in the automotive industry, allowing manufacturers to offer personalized vehicle features with unprecedented ease and precision. This technology enables the creation of unique designs, patterns, and components that can be tailored to individual preferences, enhancing customer satisfaction and providing a competitive edge in the market. From custom engraving on metal parts to intricate cutouts on exterior panels, laser cutting facilitates a level of detail and personalization that was previously difficult to achieve.

Advanced Materials

Working with advanced materials such as high-strength steels, aluminum, and composites is essential for the development of safer, more efficient vehicles. Laser cutting technology excels in processing these materials, maintaining precision and integrity even with the toughest alloys and composites. The ability to cut through high-strength steels enables the production of lighter, yet durable, vehicle structures, while the precision in cutting aluminum and composites supports the industry’s shift towards lightweight materials for improved fuel efficiency and performance.

Integration with Other Manufacturing Technologies

Laser cutting integrates seamlessly with other manufacturing technologies, such as welding, forming, and additive manufacturing, to create complex components and assemblies. This integration enhances the manufacturing process’s flexibility and efficiency, allowing for the development of components that are optimized for performance and manufacturability. For example, laser cutting can be used to prepare parts for welding with extreme accuracy or to cut intricate shapes that complement additive manufactured components, facilitating innovative designs and constructions.

Improving Efficiency and Sustainability in Automotive Manufacturing

Reducing Waste

One of the significant advantages of laser cutting is its ability to minimize material wastage. The precision of laser cutting means that parts can be nested closely together on a sheet of material, maximizing utilization and reducing scrap. This not only makes the manufacturing process more sustainable but also reduces costs associated with material procurement and waste disposal.

Energy Efficiency

Laser cutting is also recognized for its contribution to energy efficiency in the automotive manufacturing process. Modern laser cutting machines are designed to consume less energy than traditional mechanical cutting methods, contributing to lower overall production costs and reducing the environmental impact of manufacturing operations. This efficiency, combined with the speed of laser cutting, enables manufacturers to achieve higher throughput with less energy consumption.

Contributing to Lightweighting Strategies

The precision of laser cutting plays a vital role in automotive lightweighting strategies. By enabling the use of advanced materials and facilitating intricate designs, laser cutting contributes to the production of lighter components without compromising strength or safety. This reduction in vehicle weight is crucial for enhancing fuel efficiency and reducing emissions, aligning with the automotive industry’s goals for sustainability and environmental responsibility.

Challenges and Solutions in Automotive Laser Cutting

Material Compatibility

While laser cutting is versatile, challenges arise when working with a diverse range of materials used in automotive manufacturing. Different materials require adjustments in laser settings, such as power, speed, and focus, to achieve optimal results. Manufacturers overcome these challenges by leveraging advanced sensors and control systems that automatically adjust parameters for different materials, ensuring consistent quality and efficiency.

Maintaining Precision in High-Volume Production

Ensuring consistent precision in high-volume production is crucial for automotive manufacturers. Advanced calibration and real-time monitoring technologies are employed to maintain the accuracy of laser cutting machines, even under continuous operation. These technologies help identify and correct potential deviations early, ensuring that each part meets stringent quality standards.

Safety Considerations

The high-powered lasers used in cutting applications pose potential safety risks, including burns and eye damage. Manufacturers address these concerns by implementing strict safety protocols, such as enclosed cutting areas, safety interlocks, and protective eyewear. Additionally, ongoing training for operators and maintenance personnel ensures that safety measures are understood and followed, minimizing the risk of accidents in the workplace.

The Future of Laser Cutting in the Automotive Industry

Emerging Trends

The future of laser cutting in automotive manufacturing looks promising, with several emerging trends poised to further revolutionize the industry. Innovations in laser technology, such as the development of more powerful and efficient laser systems, are expected to enhance cutting speed and material versatility, enabling even more complex and intricate designs. Additionally, the integration of new materials into automotive production, such as ultra-high-strength steels and advanced composites, will continue to drive the need for advanced laser cutting solutions that can handle these challenging materials with ease and precision.

Another significant trend is the increased use of fiber lasers, which offer advantages in terms of energy efficiency, cutting speed, and maintenance over traditional CO2 lasers. Fiber lasers’ ability to cut reflective materials without back reflections damaging the equipment makes them particularly suited for automotive applications involving aluminum and copper components.

The Role of Automation and AI

Automation and artificial intelligence (AI) are set to play a pivotal role in the evolution of laser cutting technology in the automotive industry. Automation of laser cutting processes enables continuous operation with minimal human intervention, increasing production rates and reducing the likelihood of errors. AI, on the other hand, can optimize cutting paths, adjust settings in real-time based on material feedback, and predict maintenance needs to prevent downtime. This integration of AI into laser cutting systems not only enhances precision and efficiency but also allows for adaptive cutting strategies that can adjust to the unique requirements of each component and material type.

Moreover, the advent of smart factories, where laser cutting machines communicate with other manufacturing systems and devices, will lead to more streamlined and cohesive production lines. These advancements in automation and AI will enable automotive manufacturers to respond more swiftly to market changes and customer demands, facilitating the production of customized and high-quality vehicles at a faster pace.

Conclusion

The industry’s ability to adapt and embrace these advancements will be crucial in meeting the future challenges of automotive production, including the demand for more complex designs, the need for sustainability, and the shift towards electric and autonomous vehicles. The continued evolution of laser cutting techniques promises not only to enhance the manufacturing process but also to contribute to the development of safer, more efficient, and more environmentally friendly vehicles.