Introduction

Today, we’re diving into the captivating world of sheet metal manufacturing. If you’ve ever wondered how technological advancements have shaped this industry, this article is for you. From CNC Cutting to sustainable practices, let’s explore how the sector has evolved.

Historical Perspective: From Manual to Machine Operations

In the past, sheet metal manufacturing was primarily a manual process. Skilled workers used hand tools to cut, shape, and assemble metal pieces. However, as the demand for precision and volume grew, the industry began to integrate machinery into its operations. For example, CNC Cutting—a computer-controlled process—became a game-changer, allowing for more precise and consistent results than manual methods. Similarly, the use of stainless steel splashbacks in various applications can be traced back to advances in cutting techniques.

Modern Innovations: CNC and Automation

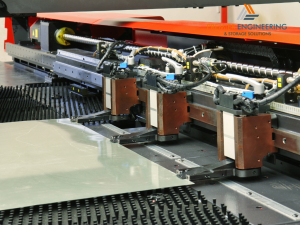

Nowadays, the field has been revolutionized by technologies like CNC Machining and Automation. These advancements allow for complex shapes to be made with high precision. Automation also increases efficiency, enabling manufacturers to meet higher demands without compromising quality. Laser cutting is another innovative technology, particularly useful in crafting intricate designs on sheet metal. For instance, this method can be employed in creating detailed metal storage cabinets.

Software for Design and Simulation

In addition to hardware, software plays a significant role. Design software helps engineers and designers draft detailed models before the manufacturing process begins. Meanwhile, simulation software predicts how the metal will behave under different conditions. Both types of software work in harmony to optimize the production process. Importantly, these software solutions often include features for CNC Punching, which is vital for creating holes in metal components, often seen in various storage solutions.

The Role of Artificial Intelligence and Machine Learning

You might be surprised to hear that Artificial Intelligence (AI) and Machine Learning have started making their way into sheet metal manufacturing. These technologies analyze data to optimize production, reduce waste, and even predict maintenance needs for machines. By doing so, they contribute to cost savings and efficient operations.

Future Trends: Sustainability and 3D Printing

Looking ahead, sustainability is becoming a major focus. Manufacturers are increasingly using eco-friendly practices and materials. For example, recycled metal is now more commonly used than ever before. Another exciting development is 3D printing, which allows for rapid prototyping and even production of metal parts. This technology promises to open new doors for customization and quick turnarounds.

Conclusion

The sheet metal manufacturing industry has come a long way, thanks to technological innovations. From the days of manual labor to the use of advanced software and AI, the sector is in a state of constant evolution. As we look to the future, sustainable practices and advanced technologies like 3D printing are set to further revolutionize the industry. In a nutshell, whether you’re interested in CNC Machining or exploring sustainable storage solutions, the realm of sheet metal manufacturing is rich with opportunities for learning and growth.