Welding plays a pivotal role in the infrastructure of Sydney’s bustling industrial and commercial sectors. The skillful fusion of materials creates the backbone for countless structures, machinery, and even intricate architectural designs that define our urban landscape. Among these applications, stainless steel fabrications stand out for their durability and aesthetic appeal.

Notably, stainless steel splashbacks have become a hallmark in various commercial projects, serving as both functional and decorative elements in kitchens, laboratories, and other spaces. The integration of such features underscores the comprehensive capabilities of welding services in Sydney, addressing not just the structural needs but also the nuanced demands of modern commercial interiors.

The Role of Welding in Industrial and Commercial Constructions

Understanding Welding Applications

Welding services in Sydney are integral to constructing and maintaining the city’s industrial and commercial infrastructure. This includes the creation of supportive frameworks, the assembly of machinery, and the crafting of decorative elements that meet both aesthetic and functional requirements. The versatility of welding allows for the customization of solutions to fit the specific needs of any project, making it indispensable in the development of robust and reliable constructions.

Stainless Steel in Commercial Spaces

The use of stainless steel splashbacks exemplifies the union of functionality and design in commercial environments. These features are prized for their hygienic surface, ease of cleaning, and sleek appearance, enhancing the overall ambiance of spaces intended for food preparation, scientific research, and more. The welding of stainless steel demands a high level of expertise to ensure that the final product is not only visually pleasing but also meets the stringent standards required for commercial applications.

Selecting a Welding Service for Large-Scale Projects

Criteria for Selection

When it comes to selecting welding services in Sydney for large-scale industrial and commercial projects, several key factors come into play. The choice of a welding provider should be based on their proven experience, the range of services they offer, and their ability to work with specialized materials like stainless steel. Additionally, their commitment to safety, quality assurance, and adherence to project timelines are crucial considerations that can significantly impact the success of a project.

Special Considerations for Stainless Steel Fabrications

For projects involving stainless steel fabrications, such as splashbacks, selecting a welding service with specific expertise in stainless steel is paramount. This ensures that the welding not only maintains the structural integrity of the material but also preserves its aesthetic qualities, including its lustrous finish. The right provider will understand the nuances of working with stainless steel, including how to clean stainless steel splashback surfaces post-installation to retain their appearance and hygienic properties.

Maintaining Stainless Steel Fabrications: How to Clean Stainless Steel Splashback

Routine Cleaning Tips

Keeping stainless steel splashbacks clean and shiny is crucial for maintaining both their appearance and hygiene. For daily cleaning, a soft cloth or sponge, warm water, and a mild detergent are often all that’s needed. It’s important to wipe in the direction of the steel grain to prevent streaks. For a sparkling finish, drying the surface with a towel or cloth after washing can prevent water spots. Regular cleaning not only keeps the splashback looking its best but also prolongs its lifespan by preventing buildup and corrosion.

Dealing with Tough Stains and Scratches

Tough stains, such as those from hard water or burnt food, may require a bit more effort. A paste made from baking soda and water can be gently rubbed onto the stain with a soft cloth, following the steel’s grain. For scratches, specialized stainless steel cleaners and non-abrasive pads can be used to gently buff the area without further damaging the surface. It’s crucial, however, to avoid harsh chemicals or abrasive materials that can degrade the stainless steel’s protective layer. For persistent issues, consulting with a professional can ensure that the integrity and appearance of the splashback are preserved.

The Importance of Professional Installation and Maintenance

Ensuring Longevity through Expert Installation

The installation of stainless steel fabrications, such as splashbacks, significantly benefits from professional expertise. Welding services in Sydney that specialize in stainless steel can ensure that installations are not only aesthetically pleasing but also structurally sound. Proper installation reduces the risk of damage and wear over time, thereby ensuring the longevity of the splashback. Professionals understand the nuances of working with stainless steel, including accommodating for expansion and ensuring seamless joins, which are vital for the durability and functionality of the splashback.

Ongoing Care and Maintenance Support

After installation, the role of welding professionals in the maintenance of stainless steel splashbacks remains critical. Many welding services offer ongoing care and repair support, helping to address any wear, damage, or corrosion that may occur over time. This support can include professional cleaning, scratch removal, and structural repairs, ensuring that the splashback maintains its hygiene and visual appeal. Engaging with professionals for regular maintenance can also prevent small issues from becoming significant problems, safeguarding the investment in quality stainless steel fabrications.

Innovations in Welding Techniques for Stainless Steel

Advancements in Welding Technology

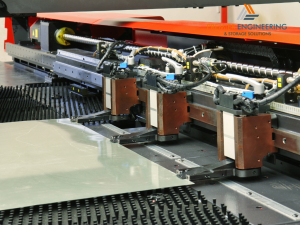

The welding landscape, especially concerning stainless steel fabrications, is continuously evolving with technological advancements that enhance both the quality and efficiency of welds. New techniques such as laser welding, friction stir welding, and advanced gas tungsten arc welding have revolutionized how stainless steel components are fused, offering unparalleled precision, speed, and strength in joins. These advancements not only improve the structural integrity of stainless steel fabrications but also significantly reduce the occurrence of welding defects, such as warping or corrosion susceptibility, which can affect the long-term durability and appearance of the material.

Impact on Cleaning and Maintenance

These innovations in welding technology have a direct impact on the cleaning and maintenance of stainless steel splashbacks. With cleaner, more precise welds, there are fewer crevices where dirt and bacteria can accumulate, making stainless steel surfaces easier to clean and maintain. Additionally, the enhanced structural integrity of welded joints extends the lifespan of splashbacks, ensuring they retain their aesthetic appeal without the need for frequent repairs or replacements. As a result, advancements in welding techniques contribute not only to the quality of stainless steel fabrications but also to their practicality in high-use environments.

Conclusion

The journey through the realms of welding services in Sydney and the care of stainless steel splashbacks highlights the critical role of professional expertise in achieving both aesthetic appeal and functional durability in commercial spaces. The evolution of welding techniques underscores the industry’s commitment to innovation, ensuring that stainless steel fabrications not only meet but exceed the demands of modern industrial and commercial applications.

Choosing the right welding services for your project is more than just a procurement decision; it’s a partnership that impacts the longevity, functionality, and visual quality of your stainless steel installations. With a dual focus on quality fabrication and ease of maintenance, stainless steel splashbacks and other fabrications promise to offer enduring value, blending seamlessly into the operational and aesthetic requirements of any space.